Introduction to Book Binding Machines

The perfect binding machine has become a cornerstone technology within the book production industry. As a prevalent method for creating durable, professional-quality publications, it is an indispensable asset for commercial printers, publishing houses, and independent authors alike. This overview outlines key considerations for selecting the optimal equipment to meet specific binding requirements.

Benefits of Using a Book Binding Machine

Employing a perfect binding system delivers distinct advantages. It produces a polished, robust finish where adhesive securely bonds pages, ensuring longevity. A significant benefit is the resulting lay-flat capability, which greatly enhances readability and user experience. Furthermore, these systems are designed for high-output efficiency, capable of processing multiple units simultaneously to meet substantial production demands. Their operational simplicity also makes them accessible, suiting both seasoned professionals and those new to the binding process.

Factors to Consider When Choosing a Book Binding Machine

Selecting the most suitable perfect binding machine requires a methodical evaluation of several core operational and technical factors to align with your business’s specific output demands.

Assessing Production Capacity and ThroughputThe primary consideration is the machine’s production capacity, which must match your projected workload. This involves two key metrics: the maximum book thickness (spine width) it can process and its binding speed, typically measured in cycles per hour. Accurately estimating your average and peak production volumes is essential to ensure the chosen model can handle your daily or weekly output without becoming a bottleneck.

Evaluating Operational Performance and Long-Term ReliabilityBeyond sheer output, the machine’s operational efficiency and build quality are critical. Evaluate the user interface and automation features that contribute to consistent results and operator ease. Most importantly, prioritise durability and reliability by examining the machine’s construction and the manufacturer’s reputation for robust engineering. Investing in a high-quality unit from a reputable supplier is fundamental to ensuring sustained performance, minimising downtime, and achieving a strong return on investment over the long term.

Different type Book Binding Machines

The market offers several distinct types of adhesive binding systems, each employing a different bonding technology suited to specific applications. The three primary categories are hot melt, perfect binding, and PUR systems.

Hot melt binding utilises a solid thermoplastic adhesive which is heated to a liquid state for application to the book spine. As it cools, it rapidly solidifies to form a firm bond. Perfect binding refers to the standard process where a versatile hot-melt or cold-glue adhesive is applied to a roughened and trimmed spine, yielding the familiar, sleek paperback finish. In contrast, PUR (Polyurethane Reactive) binding employs a moisture-curing adhesive that creates an exceptionally flexible and durable bond, offering superior resistance to temperature extremes and frequent handling.

Top Features to Look for in a Book Binding Machine

When selecting a glue book binding machine, it’s essential to consider the features that will best suit your business needs. One crucial feature is the machine’s binding capacity. Ensure that it can handle the thickness and size of the books you typically work with. Additionally, look for a machine with adjustable clamps or pressure settings to achieve consistent and precise binding results.

Modern adhesive binding systems are valued for their operational flexibility and user-centric design. A key advantage is their versatility in binding styles; advanced models can accommodate various techniques such as square back binding for a rigid, professional spine or integrate processes like saddle stitching, thereby expanding production capabilities for diverse project requirements.Equally critical is the ease of operation. Machines featuring an intuitive, user-friendly interface with clear controls and guided instructions significantly reduce the operator learning curve. This design consideration minimises setup errors, accelerates production throughput, and enhances overall workflow efficiency.

How to Select the Right Book Binding Machine for Your Business

Selecting an appropriate adhesive binding system requires a methodical assessment of your operational demands against available specifications. Begin by analysing your production volume and the typical size, spine thickness, and format of your projects to ensure the machine’s capacity aligns with your core workflow.

Subsequently, prioritise the technical features essential for your output. This includes evaluating the need for adjustable clamping mechanisms, support for multiple binding styles, or a specific adhesive type (e.g., hot melt vs. PUR). Financial considerations are paramount; establish a clear budget framework and compare not only initial costs but also the warranty terms and long-term value offered by different manufacturers. Finally, consult independent user reviews to gain practical insights into a machine’s real-world reliability, performance, and durability before finalising your investment.

Maintenance and Care for Book Binding Machines

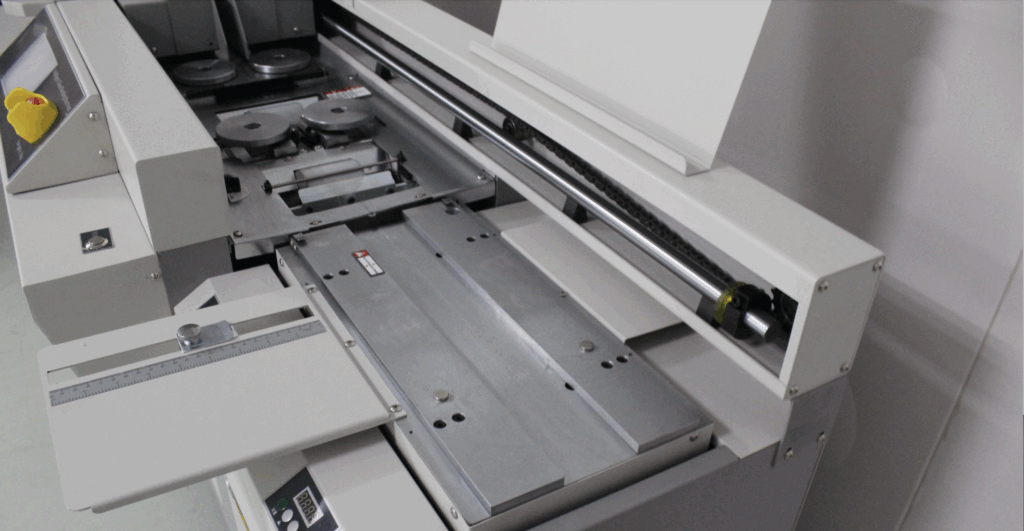

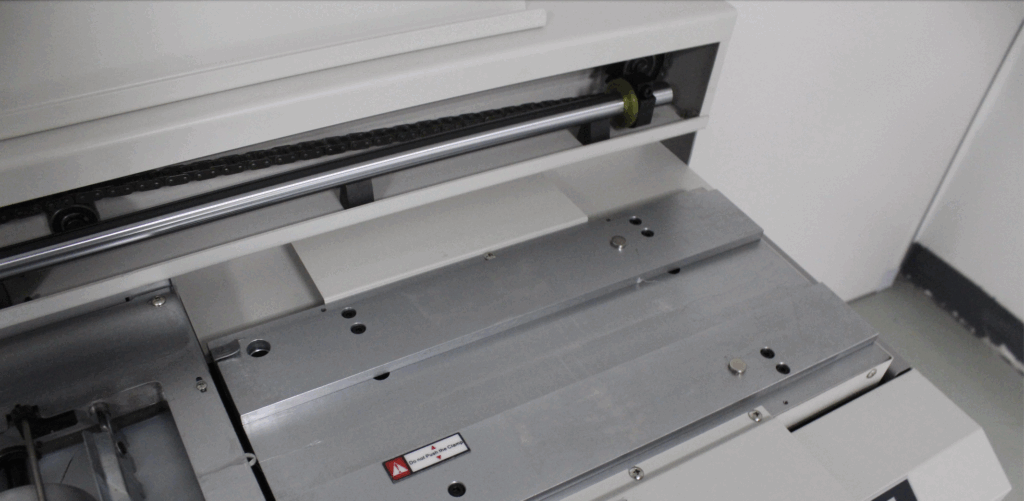

To guarantee the long-term reliability and peak performance of a perfect binding system, a disciplined regimen of preventative upkeep is paramount. Fundamental to this is maintaining stringent cleanliness; all surfaces and the adhesive application mechanism must be kept free from dust and residue in strict accordance with the manufacturer’s guidelines.

Furthermore, the lubrication of all moving components at specified intervals is critical to prevent mechanical wear and ensure consistently smooth operation. For comprehensive care, establishing a schedule for professional inspection and servicing by a qualified technician is strongly advised. This proactive measure allows for the early identification and resolution of potential issues, thereby safeguarding against operational downtime and preserving the machine’s integrity over time.

Conclusion

Selecting a high-performance perfect binding system is a strategic investment decision for any serious publishing or printing operation. A methodical evaluation process—encompassing production capacity, technical specifications, and long-term upkeep—is fundamental to identifying the optimal equipment for your requirements. A well-suited machine forms the cornerstone of efficient operations, directly correlating to the professional finish and durability of your final product while enhancing overall workflow productivity. A prudent selection, therefore, not only ensures a consistently high standard of bound output that meets client expectations but also serves to reinforce your business’s competitive standing.