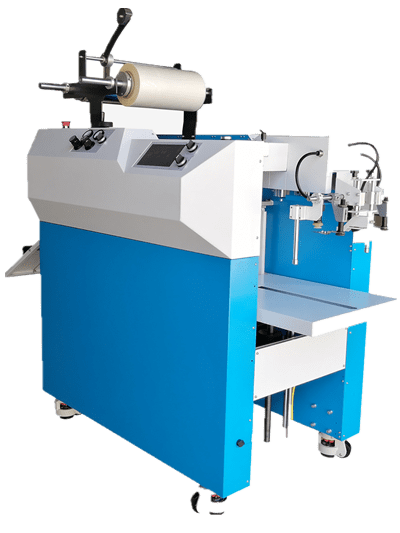

NEW automatic laminator, SF-390A

Troubleshooting for Automatic Creaser

Better design label cutter, Same price offer

How to protect yourself from COVID-19?

Here is the guide details for you and your family as below:

- Avoiding contact with people who are sick.

- Washing hands often with soap and water for at least 20 seconds. If soap and water are not readily available, using an alcohol-based hand sanitizer with at least 60% alcohol. Wash hands with soap and water if hands are visibly dirty.

- Avoiding touching eyes, nose and mouth.

- Covering a cough or sneeze with a tissue, then throwing the tissue in the trash. If no tissue, sneezing or coughing into elbow, not hands.

- Cleaning and disinfecting work areas, frequently touched objects and surfaces using a regular household cleaning spray or wipe.

- Staying home from work when sick or with a temperature of 100.4°F /38°C at any time in the previous 24 hours.

- Staying home from work for 14 days if you has been exposed to COVID-19, or has been quarantined due to travel to an affected area or exposure to the virus.

- When you are at home, try to open window 2 times, each time 30 minutes around. And clean the room each day.

- When you go out, it is better to put on mask to protect yourself and others. Because the Coronavirus disease have 14 days incubation period.

First, in what cases do you need to wear a face mask?

Wearing face masks is an effective way of blocking the spread of respiratory secretions.

- You should wear a face mask when visiting patients in the hospital, especially at fever or respiratory clinics.

- Wearing a face mask is recommended when:

1) Travel on public transport in the high-risk season of respiratory infections

2) Spend a long time in a relatively confined space, such as supermarkets, shopping malls, cinemas, etc.

3) There are sick persons in your study or work areas

4) Close contact with patients or suspected patients

3. To prevent the spread of the viruses to others, please wear a mask when symptoms of respiratory diseases such as fever, cough, and runny nose occur.

Second, how to select a face mask?

There are different types of face masks, such as industrial and medical face masks. Currently, we have four commonly used categories of face masks:

- Regular absorbent gauze face masks cannot be used for preventing infection, therefore, they are not recommended.

- Disposable medical face masks.

- Disposable medical surgical face masks consist of three layers: outer water and droplets resistance layer; middle particle filter layer; and inner moisture-absorbing layer.

- Disposable medical protective face masks (known as N95 face masks) have a 95% filter effect, surface moisture resistance, and blood-blocking properties. Disposable medical surgical face masks can be used for our daily protection. When buying, please make sure that there are “medical-surgical masks” on the outer packaging of the selected face masks

Third, how to properly wear face masks?

Always wash your hands before wearing a face mask. Avoid hand contact with the inside of the face mask to reduce the risk of contamination. Understand the inside, outside, up and down of the face masks: the light side is the inner layer and should be contacted to the mouth and nose, and the dark side is the outer layer. The metal strip (nose clip) indicates the up position of the mask. Do not wear the face mask inside out or on both sides alternately. The face mask needs to be replaced when getting wet. It is not recommended to wear a face mask for more than four hours.

How to wear disposable medical face masks and disposable medical surgical face masks?

1) Expand the fold gently and completely

2) Cover the nose, mouth, and chin. For the face mask with straps, tie the upper strap to the top of the head and lower strap behind the neck. For other face masks, hang it directly on the ears.

3) Use your fingers to adjust the nose clip according to the shape of your nose.

4) Check the contact along the edges of the mask.

How to wear disposable medical protective face masks?

1) Holds the protective face mask with one hand with the nose clip side outward. Cover the nose, mouth, and chin with the nose clip close to the face.

2) Use another hand to pull the lower strap over the head and place it under the ears behind the neck.

3) Then pull the upper strap to the middle of the head.

4) Place your fingers on the metal nose clip, starting in the middle, press the clip inward with your fingers, move and press to both sides to adjust the clip based on the shape of the nose.

How to remove the face masks?

1) Do not touch the outside of the face mask (contaminated side).

2) Untie the lower strap and then the upper strap. Hold the strap of the mask with your finger and discard it into a medical waste bin.

3) Wash hands after removing the mask.

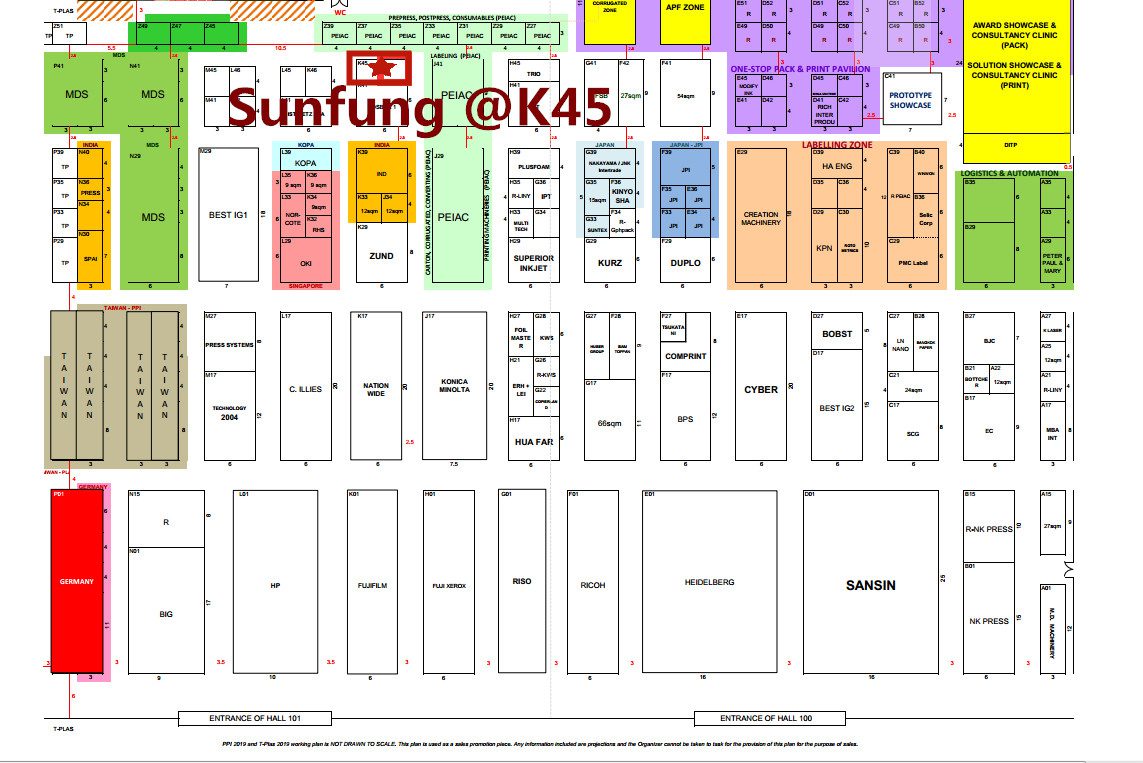

Pack Print International 2019 Invitation

NEW 460A PUR Binder

Print China 2019 Invitation

Sunfung hold business cooperation with EP Technology.

NEW Spot UV coater with cold foil in one pass

Spot UV coater with cold foil in one pass New Samples ~

A3+ Spot UV coater + Foil

Welcome to see us in All in print 2018 in Shanghai

Thanks for your kindly support!

Let us know your ideas for the NEW UV coaters from Sunfung.

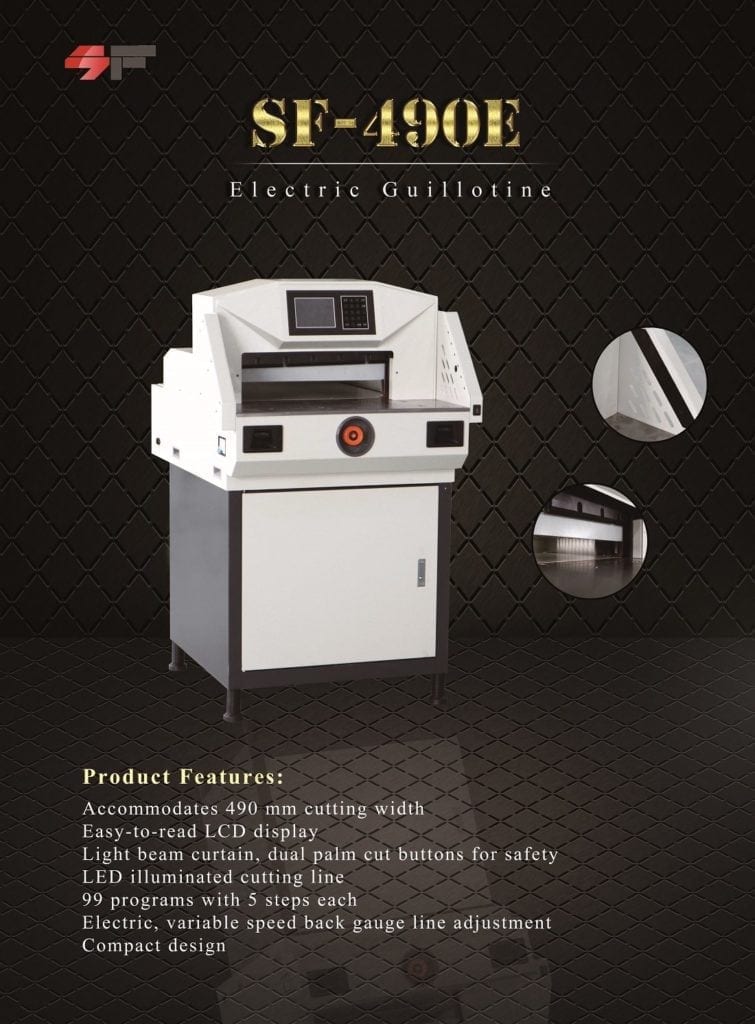

New Electric Paper Cutter, 460-490mm.

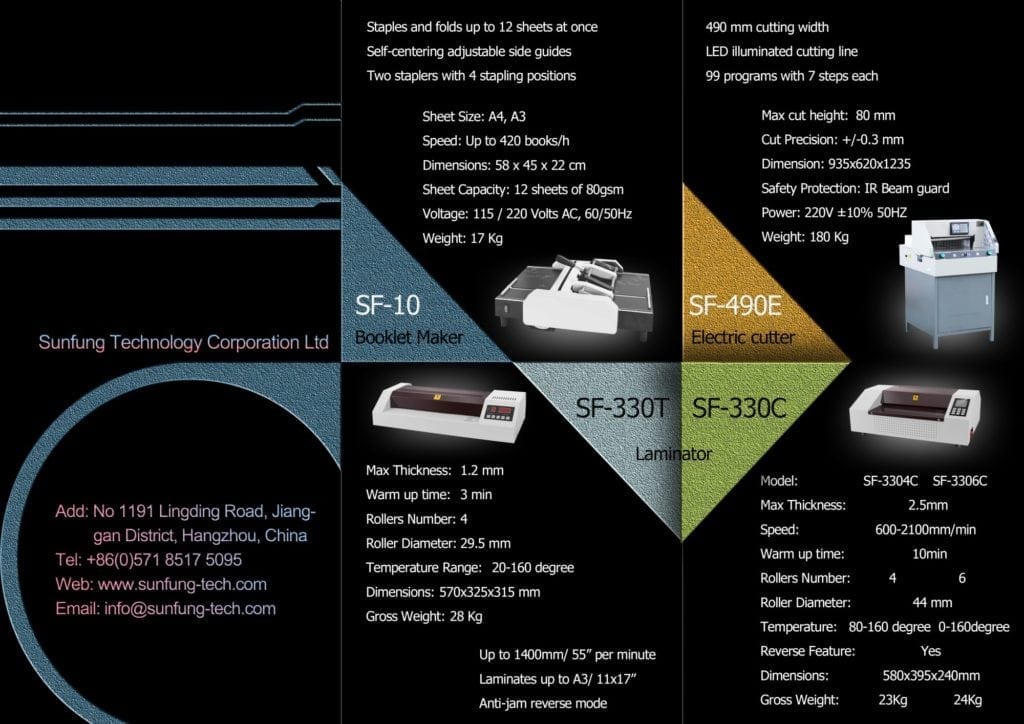

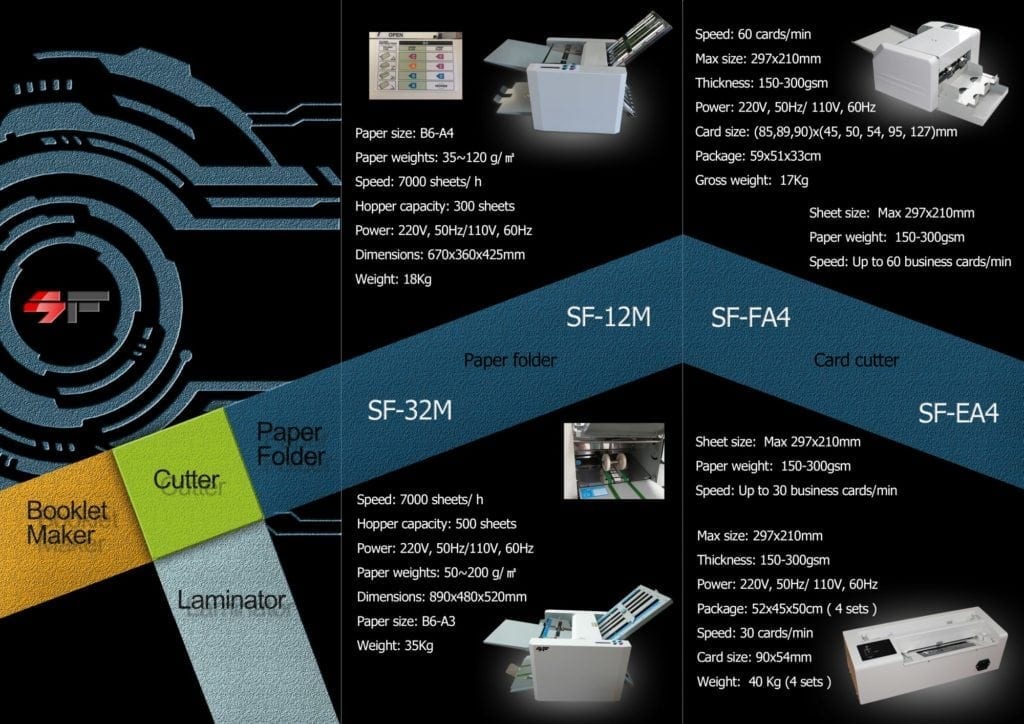

Sunfung new office products, paper folder, booklet maker, laminator, card cutter and electric cutter.

Top standard heavy duty A3 book binder for glossy paper, OEM by Sunfung in China.

Welcome to come and visit us @ Print China 2019. (Booth No: 2841, Hall 1. April 9-13th 2019)

Sunfung updated the hydraulic laminator from 390-720 mm

Welcome to come and visit us @ Printing South China 2018. ( Booth No: 5350, March 10th-12th )

New A3 Paper Folder, Same Price with Before ! Do you like it ?

Happy New Year 2018 ~

Sunfung introduce SF-360 entry level laminator, digital laminator & hydraulic laminators

Sunfung New Laminators

Sunfung newly introduce three models laminators, 360 entry laminator, digital laminator, 370 & 485 and one hydraulic laminator H485.

1) Fast laminating speed, short warm up time;

2) Auto collection & Auto separation ( bursting ) options;

3) Non-sticky heat roller;

4) Steel roller + oil inside heating;

5) 90 – 600 gsm paper available;

6) Compact design;

7) 5 years warranty;

Welcome to contact us to know more details. Also you can visit our page to check the videos or download brochures as you want.

Sunfung Team by December 12th

Inside Structure of Heavy duty cutter

0.2 mm cutting accuracy

5 Benefits Of Paper Cutting Machine SF-H80P

‘What does a paper cutter do besides cutting paper?’ – you are asking yourself.

Well, let us introduce you to our powerful circle paper cutter that boasts with some of the most advanced features on the market place. Aside from the fact that it offers the best hydraulic paper cutting and clamping both done as separate processes, it is completely adjustable for different types of clamp pressure.

1. It makes your job easier

First and foremost, our circle paper cutter is known to make the job easier for every employee that needs to trim the papers or make name cards, etc It can cut even the thick paper boards with total height for 80 mm.

2. You can make efficient paper cutting job

This paper cutting machine is adjustable and comes with over 50 programs and 16 steps/32 steps in each of them, satisfy most of your cutting jobs. Heavy duty structure, heavy cutting blade & cutting clamp guarantee a long time continue cutting.

3. It is easy to control

From the 10 inch touch screen access to the PLC control system, this paper cutter with light is easy to operate with. The power switch button with key lock and a foot pedal making the operation a lot easier.

4. It cuts through paper with utmost accuracy

Your paper designs just got to another level with this amazing rotary slicer and paper design cutter. Also known as a heavy duty paper cutting machine, this model can cut with 0.2 mm accuracy and at a maximum height of 80 millimeters and length of up to 800 millimeters.

5. It is quiet control by new design

Sunfung use the Vane pump instead of Gear pump which decreased a lot of noises, guarantee a smooth and long time working. More suitable for small to middle print shops.

Buy the Sunfung SF-H80P paper cutter and streamline all tasks in the print shops in an efficient and environmentally-friendly way!

Sunfung Technology Corporation Ltd

No 1191 Linding Road, Jianggan District, Hangzhou, CHINA

Tel: 0086 571 85175095

info@sunfung-tech.com www.sunfung-tech.com

Sunfung will attend Print 2017 from Sep 10th – 14th

Sunfung Technology will attend Print 2017 from Sep 10th – 14th. Our booth No: 3653 South Hall.

Sunfung will introduce the new tabletop booklet makers ; new laminators ; and A4 folders with A4 stacker to collect small leaflets.

Also during the exhibition period, each order you confirm, no matter for paper folders, book binders, booklet makers or paper cutters. We offer you 5% discount off at the show!

Looking forward to meet you there.

Sunfung Team