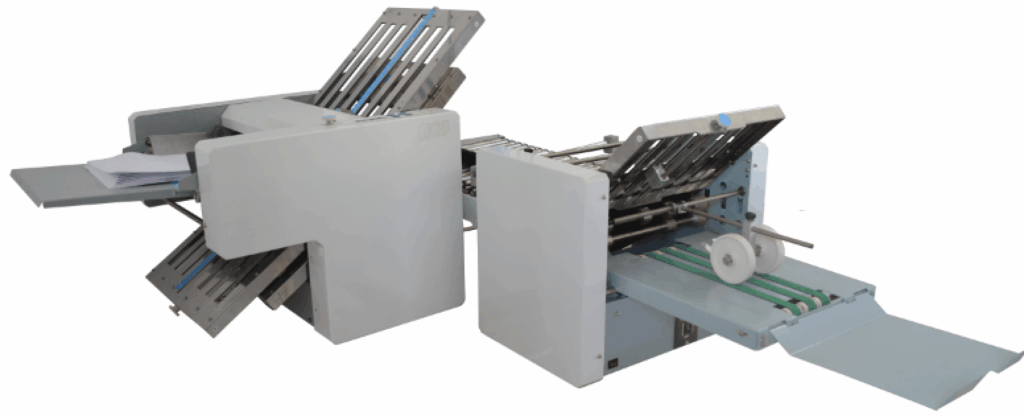

Modern paper folding machines have transformed high-volume document processing workflows. By automating the precise folding of letters, leaflets, and brochures, these systems enable businesses to achieve substantial gains in operational efficiency, reduce reliance on manual labour, and ensure flawless, uniform results. For commercial printers, direct mail operations, and any sector with recurring paper handling needs, integrating an advanced folding machine is a decisive step towards optimised throughput and exceptional finish quality.

Benefits of Using Paper Folding Machines

Automated paper folding systems deliver considerable operational advantages. Primarily, they drastically reduce processing time by swiftly handling large volumes that would be untenable for manual labour. An operator simply loads the stack, selects the required fold configuration, and initiates the cycle, ensuring each document is completed with uniform precision. This liberates unproductive labour hours for higher-value tasks.

A direct financial benefit is the significant reduction in operational expenditure. By consolidating what would require multiple personnel into a single, streamlined machine operation, businesses achieve substantial savings on labour costs. Furthermore, these machines are engineered for intuitive use, minimising the training investment needed for effective deployment.

Critically, these systems guarantee a consistently professional finish. They eliminate the variability and imperfections inherent in hand-folding, producing neat, precise, and identical results every time. This enhancement in presentation quality is vital in sectors like marketing and corporate communications, where document professionalism directly impacts brand perception and audience engagement.

Types of Paper Folding Machines

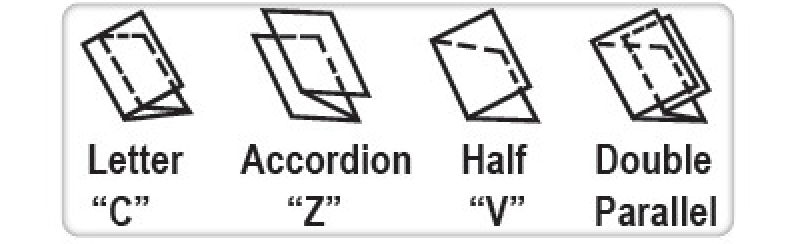

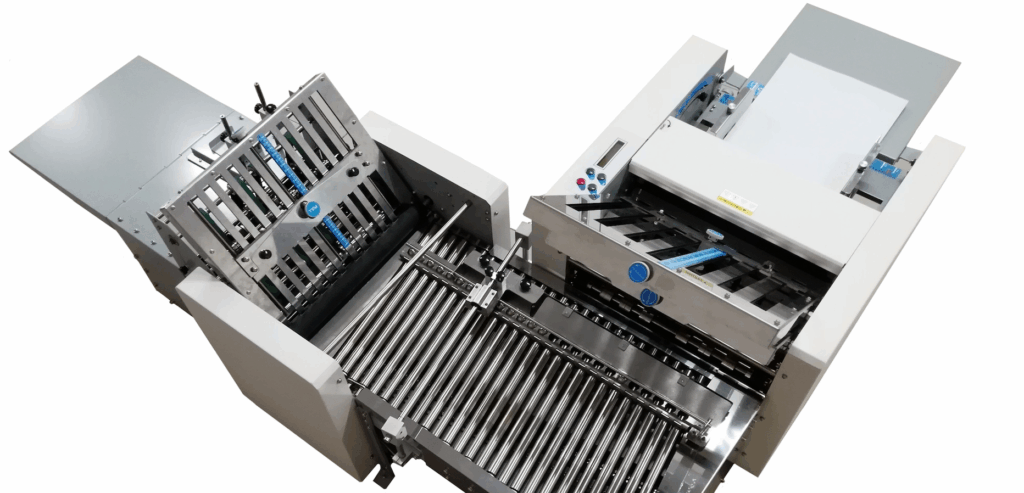

Modern paper folding systems are categorised into distinct types, each precision-engineered for specific operational demands. The most prevalent models are letter folders, accordion (or zigzag) folders, and gatefold machines.

Letter Folding Machines are the workhorses for standard business correspondence, processing items like letters, statements, and A4 sheets with high efficiency. They typically offer configurations for single, double (C-fold), and letter (Z-fold) patterns, providing flexibility for everyday mailing and filing needs.

Accordion Folding Machines handle larger-format materials such as marketing brochures, pamphlets, and menus. Their design allows for multiple parallel folds, creating compact, professional Z-folds or C-folds that enhance readability and are ideal for materials intended for direct mail or display.

Gatefold Machines produce a symmetrical, elegant finish perfect for premium print items like invitations, greeting cards, and high-impact promotional pieces. The paper is folded inward from both edges to meet at the centre, resulting in a balanced, polished presentation that elevates the perceived quality of the document.

Selecting the correct system requires a clear analysis of your primary document sizes, required fold styles, and expected volumes to ensure the chosen machine delivers optimal productivity and finish quality for your specific applications.

Factors to Consider When Choosing a Paper Folding Machine

Selecting the optimal paper folding system requires a strategic evaluation of several core operational and technical specifications. A methodical approach ensures your investment aligns perfectly with your workflow demands and delivers a strong return.

Key Decision Factors for Your Business

1. Evaluate Your Daily Throughput Begin by analysing your average and peak daily folding volume. For environments with high-volume, continuous output, investing in a machine with a superior sheet capacity and a robust duty cycle is essential to prevent bottlenecks and maintain productivity.

2. Assess Fold Versatility and Precision The range of available fold patterns (e.g., letter, accordion, gatefold) is critical. Furthermore, prioritise machines that offer micro-adjustable settings for fold placement. This precision allows for perfect calibration to your specific paper stocks and finishes, ensuring consistent, professional results.

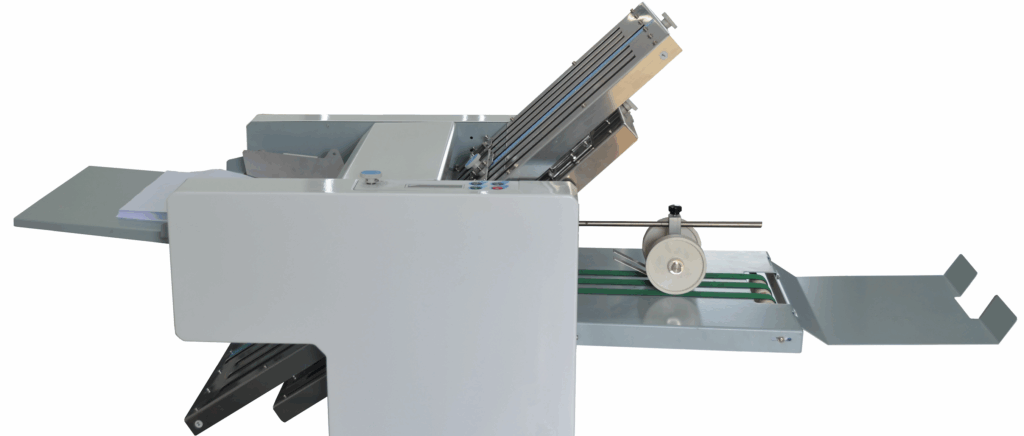

3. Prioritise Operational Speed and Footprint The machine’s rated speed (sheets per hour) directly impacts processing time. For time-sensitive operations, a high-speed model is crucial. Concurrently, measure your available workspace accurately. Machines vary significantly in size, and selecting a model with a compact, efficient footprint that fits your designated area is a practical necessity.

4. Verify Build Quality and Support Long-term reliability is paramount. Invest in a machine built with durable, commercial-grade components from a reputable manufacturer. Crucially, review the terms of the warranty and the availability of responsive customer and technical support to safeguard your operation against extended downtime.

By systematically assessing these factors—volume, versatility, speed, space, and support—you can confidently select a folding machine that enhances efficiency, reduces costs, and grows with your business needs.

Common Features and Functionalities of Paper Folding Machines

Modern paper folding systems are equipped with sophisticated features engineered to maximise throughput, ensure precision, and minimise operational intervention. Key functionalities to prioritise include:

High-Capacity Automated Feeding: A continuous, automated feeding system removes the need for manual sheet feeding, enabling consistent, unattended operation for large-volume jobs and significantly boosting productivity.

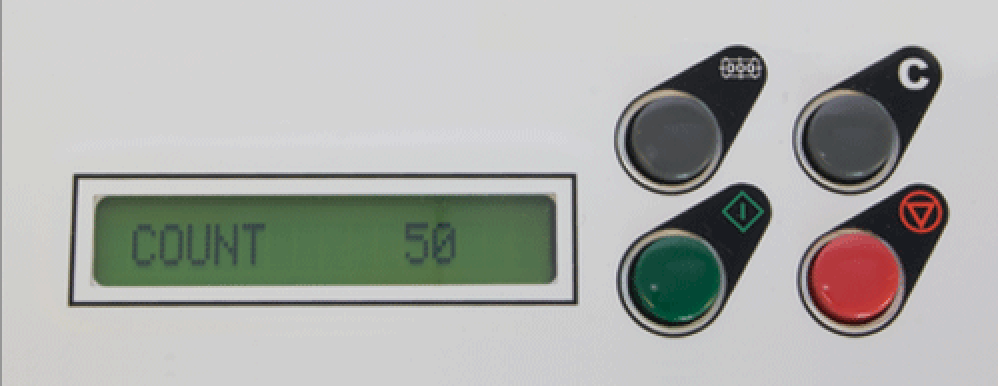

Modular & Programmable Folding: Look for machines with multiple, quick-adjust fold plates for flexibility across common fold patterns. Advanced models feature digital memory settings, allowing users to save and instantly recall precise configurations for different paper types and fold styles, eliminating recalibration.

Enhanced Process Automation & Control: Programmable batch counters automate the processing of set quantities, while integrated intelligent jam detection systems promptly halt operation and alert the user to issues, protecting the machinery and reducing downtime. Some systems also include automatic counting and stacking for streamlined post-folding handling.

Selecting a machine with the right combination of these features—tailored to your specific document types, volumes, and workflow—is crucial for achieving optimal efficiency, reliability, and a strong return on your investment.

How to Maximize Efficiency with Paper Folding Machines

To achieve peak operational efficiency with a paper folding system, implementing targeted procedural strategies is essential. Adhering to the following best practices will optimise throughput, ensure consistent quality, and extend equipment longevity.

1. Streamline Pre-ProcessingBegin with a streamlined workflow by sorting and organising all materials prior to folding. This preparatory step minimises handling time during machine loading and prevents workflow interruptions.

2. Utilise Programmable PresetsLeverage the machine’s digital memory by creating and storing precise presets for all standard fold patterns and paper weights. This eliminates manual recalibration between jobs, ensuring repeatable accuracy and saving significant setup time.

3. Ensure Optimal Paper LoadingCorrectly prepare paper stacks by ensuring edges are uniformly aligned and sheets are free from static, curls, or adhesions. Proper fanning and alignment are critical to preventing misfeeds and jams, thereby maintaining a smooth, continuous operation.

4. Enforce a Preventative Maintenance ScheduleStrictly adhere to the manufacturer’s prescribed maintenance regimen. Regular cleaning of feed paths, rollers, and fold plates, combined with scheduled professional servicing, is fundamental to preventing mechanical wear and ensuring reliable, long-term performance.

5. Invest in Comprehensive Operator TrainingEnsure all personnel are thoroughly trained not only in basic operation but also in advanced functionalities, routine troubleshooting, and proper maintenance procedures. High operator proficiency directly reduces errors, minimises waste, and maximises overall productivity.

By integrating these core strategies—preparation, preset optimisation, correct loading, diligent maintenance, and skilled operation—you will fully capitalise on your investment, transforming the folding machine into a cornerstone of an efficient, high-quality document finishing line.

Precision and Accuracy with Paper Folding Machines

Precision-engineered paper folding systems deliver exceptional accuracy, ensuring every fold is meticulously consistent and dimensionally exact. To achieve and sustain this high standard of performance, a methodical approach to machine selection, calibration, and operation is essential.

Ensuring Optimal Folding Precision

1. Select a Purpose-Built SystemThe foundation of accuracy lies in choosing a machine specifically engineered for your required fold patterns and production volume. Different models offer varying tolerances; selecting one designed for your most frequent applications is paramount.

2. Implement Rigorous Calibration and MaintenanceSustained precision depends on a strict calibration and servicing schedule. Over time, mechanical components can drift. Adhering to the manufacturer’s guidelines for regular adjustment and professional maintenance is crucial to correct any variance and maintain peak accuracy.

3. Use Appropriate Paper StockThe weight, grain direction, and finish of the paper significantly influence the fold quality. Thin or unsuitable stocks may not feed or crease cleanly. For optimal results, always use paper that is compatible with both the machine’s specifications and the intended fold style.

By integrating these three principles—targeted machine selection, disciplined maintenance, and appropriate materials—you will consistently achieve the flawless, professional results that automated folding technology is designed to provide.

Maintenance and Care for Folding Machines

To guarantee the long-term reliability and precision of your paper folding system, a disciplined preventative maintenance protocol is non-negotiable. Adhering to these core practices safeguards your investment and ensures consistent, high-quality output.

Essential Maintenance Protocol

1. Systematic CleaningPerform regular cleaning to remove paper dust and particulate debris from the feed path, fold plates, and rollers using a soft, lint-free cloth or brush. This prevents accumulation that can cause misfeeds, jams, and inaccurate folding.

2. Scheduled LubricationConsult the manufacturer’s manual to identify any components requiring periodic lubrication. Apply only the specified lubricant at recommended intervals to moving parts such as gears and bearings to minimise wear and ensure smooth, quiet operation.

3. Routine Inspection and CalibrationConduct frequent visual inspections for loose fittings or signs of wear. Most critically, verify and calibrate the alignment of fold plates and feeding mechanisms to maintain absolute dimensional accuracy in every fold, as even minor misalignment degrades finish quality.

4. Use of Compatible MaterialsAlways use commercial-grade paper within the machine’s specified weight and grain direction tolerances. Inferior or unsuitable stock is a primary cause of operational issues, including jams and poor fold definition, which strain the mechanism.

5. Professional Technical SupportFor complex adjustments, performance declines, or fault diagnosis, engage a qualified service technician. Authorised professionals possess the tools and expertise for thorough calibration and repairs, preventing minor issues from escalating into costly downtime.

Implementing this structured approach—clean, lubricate, inspect, calibrate, and seek expert support—is fundamental to achieving optimal machine longevity, sustained productivity, and flawless finished results.

Conclusion: Investing in a Paper Folding Machine

In the contemporary commercial landscape, achieving peak operational efficiency and precision is paramount. Integrating a professional paper folding system can substantially elevate productivity, curtail manual labour expenses, and guarantee consistently accurate finishing. For commercial printers, mailing operations, and any sector with regular document handling needs, such a machine constitutes a strategic operational asset.

A methodical selection process—assessing your specific document volumes, types, and required functionalities—is essential when choosing a unit. Furthermore, a proactive maintenance regimen is critical to preserving the equipment’s condition and ensuring reliable, long-term performance.

By adhering to the structured principles outlined here, you can fully optimise the efficiency and output quality of your folding system, thereby enhancing the overall proficiency and competitiveness of your business operations.