Introduction to Commercial Paper Cutting Machines

Commercial paper cutters represent a transformative advancement within the paper processing sector. These robust and precise instruments have redefined efficiency for operations requiring high-volume or high-accuracy cutting. Essential for diverse professional environments, from commercial printing houses to packaging enterprises, they deliver the consistent performance necessary for demanding industrial and office tasks.

How Commercial Paper Cutting Machines Work

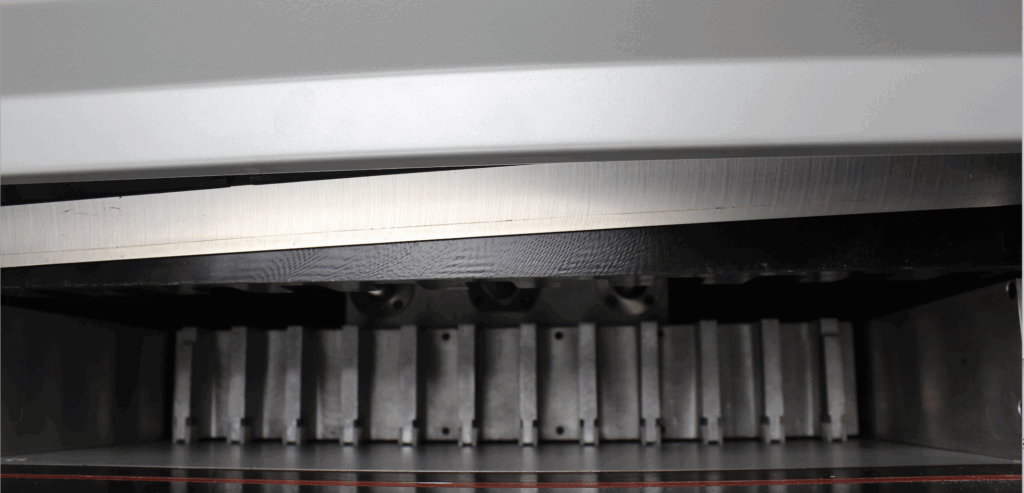

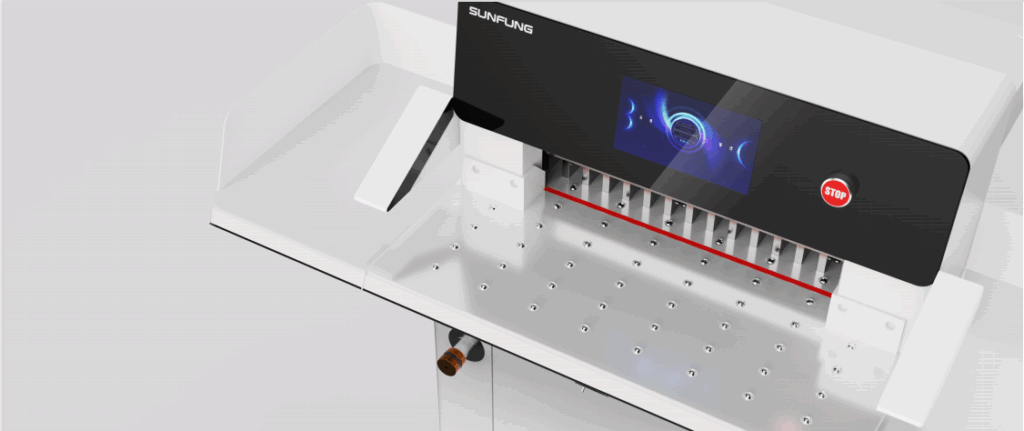

Engineered for enhanced productivity, commercial paper cutters deliver rapid, precise, and consistent results. They utilise robust, guillotine-style blades capable of cleanly shearing through substantial reams in a single operation. This automated process removes the inconsistencies of manual cutting, minimising error.

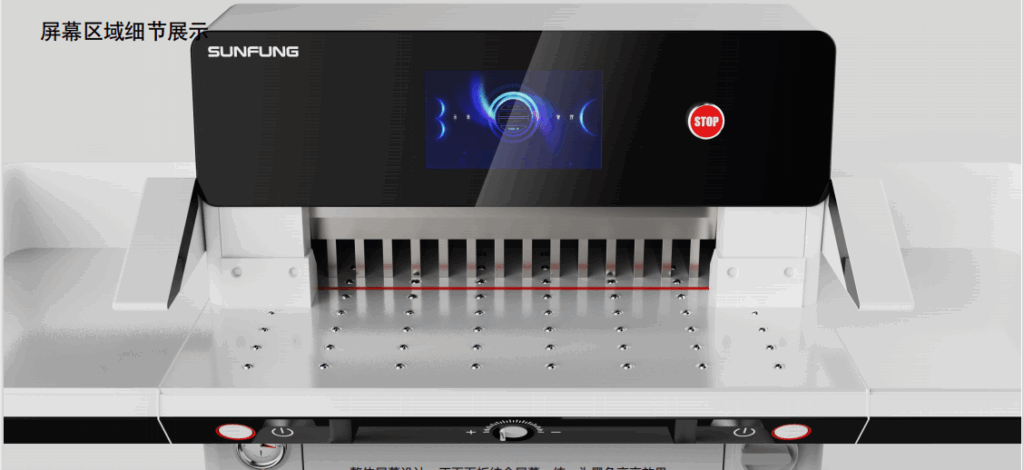

Operation involves positioning the paper stack on the machine’s bed and selecting the desired measurements. The system then automatically aligns and executes impeccably straight cuts. Sophisticated models feature digital interfaces and programmable memory, allowing users to save and repeat complex jobs for peak repeatability and efficiency.

Benefits of Using a Commercial Paper Cutting Machine

Employing a commercial paper cutter provides distinct advantages for any business scale. A primary benefit is the considerable saving of time and a corresponding rise in output. Manual trimming is a labour-intensive task, particularly with high volumes, whereas an automated machine drastically accelerates throughput, enabling faster project completion and adherence to demanding schedules.

Furthermore, these machines guarantee precision and uniformity. Hand-cutting often leads to irregular edges, resulting in material waste and an unprofessional finish. A commercial cutter delivers consistently exact cuts every time, ensuring a high-quality, standardised result.

Critically, these machines also enhance workplace safety. Manually slicing through large stacks poses a risk. Commercial cutters are designed with integrated safety guards, significantly reducing the chance of accidental injury. This proactive measure protects staff and mitigates potential operational liabilities.

Different Types of Commercial Paper Cutting Machines

Commercial paper cutters are categorised into distinct types, each engineered for specific operational demands. The most prevalent models are guillotine, rotary, and stack cutters.

The guillotine cutter, renowned for its straightforward design and adaptability, employs a long, descending blade to slice through large paper reams. It is suitable for a wide variety of paper formats and weights. Conversely, the rotary trimmer utilises a circular, rotating blade ideal for detailed, precise work, such as trimming photographs or business cards, where exceptional edge quality is paramount.

For high-volume industrial environments, the heavy-duty stack cutter is essential. It is built to process exceptionally thick piles of materials in one efficient pass, making it a staple in large-scale printing and packaging operations.

Selecting the appropriate machine necessitates a careful evaluation of your business’s specific paper volumes, required precision, and material types. Comparing technical specifications, functionalities, and verified user feedback is crucial for a sound investment.

Factors to Consider When Choosing a Commercial Paper Cutting Machine

Selecting a commercial paper cutter requires careful assessment of several technical and operational specifications to ensure a suitable long-term investment.

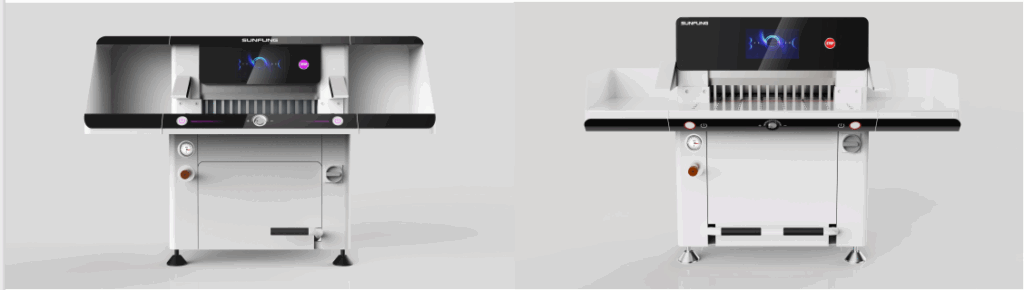

Cutting Capacity & Size: Primarily, assess the machine’s maximum sheet capacity (stack height) and its bed size. For high-throughput tasks, a model with a greater capacity is essential, and the bed must accommodate your standard or largest paper format.

Functional Versatility: Evaluate the cutting operations supported. Beyond straight cuts, consider if you require capabilities such as angled trimming, perforation, or creasing (scoring). Choose a machine whose functionalities align with your project demands.

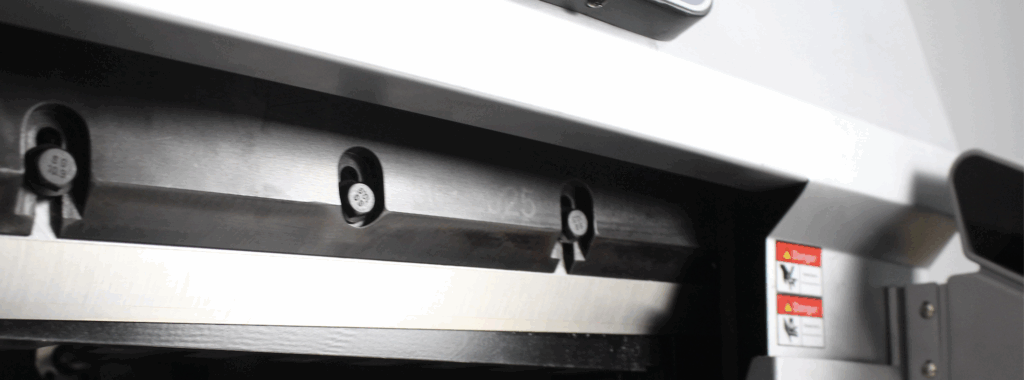

Critical Safety & Usability: Operator safety is paramount. Prioritise models with integrated safety features like enclosed cutting mechanisms and dual-hand operation controls. Ease of use, facilitated by intuitive digital interfaces and programmable memory functions, enhances both safety and daily efficiency.

Build Quality & Support: Finally, consider the machine’s construction for durability under constant use and investigate the availability of servicing and spare parts to ensure operational longevity.

A methodical evaluation of these factors will guide a strategic procurement decision, ensuring the equipment yields optimal productivity and value for your business.

Tips for Operating a Commercial Paper Cutting Machine Safely

Safety remains the foremost concern in the operation of any commercial paper cutter. Adhering to established protocols is essential for safeguarding personnel and ensuring a secure work environment.

Consult the Manual: Prior to use, thoroughly review the manufacturer’s manual to understand all operational procedures and specific safety warnings.

Utilise Personal Protective Equipment (PPE): Operators must consistently wear appropriate safety goggles and protective gloves to shield against potential injury.

Maintain a Clear Workspace: Ensure the immediate work area is kept free from clutter, such as loose materials or tools, which could obstruct the process or cause accidents.

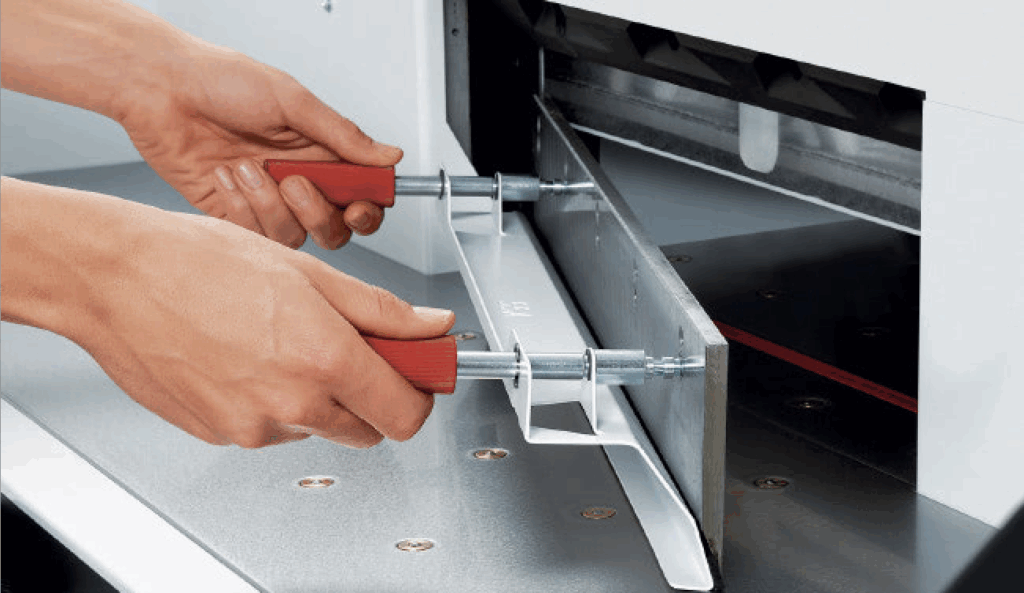

Secure Material Correctly: Before cutting, verify that the paper stack is perfectly aligned and firmly clamped in place to prevent any slippage during the guillotine action.

Engage All Safety Mechanisms: Always use the integrated safety features, including blade guards and dual-hand activation switches. These are designed to prevent accidental operation and must be functional at all times.

Conduct Routine Servicing: Follow a strict maintenance schedule as specified by the manufacturer. This includes regular blade inspection, lubrication of moving components, and general cleaning to sustain optimal and safe performance.

By rigorously implementing these measures, the risk of workplace incidents can be significantly reduced, promoting a culture of safety and operational reliability.

Maintenance and Troubleshooting of Commercial Paper Cutting Machines

Regular maintenance is crucial to keep your commercial paper cutting machine in top condition. Here are some maintenance tasks you should perform regularly:

Blade Sharpening: Over time, the blades of the cutting machine can become dull. Sharpen the blades periodically to ensure clean and precise cuts. You can do this yourself using a sharpening stone or seek professional assistance.

Cleaning: Remove any paper dust or debris that may accumulate on the machine. Use a soft brush or a cloth to gently clean the cutting platform, blades, and other parts of the machine. Avoid using harsh chemicals that can damage the machine.

Lubrication: Apply a small amount of oil to the moving parts of the machine to reduce friction and ensure smooth operation. Consult the machine’s manual for the recommended lubrication intervals and the type of oil to use.

If you encounter any issues with your commercial paper cutting machine, here are some common troubleshooting steps:

Uneven Cuts: If the machine is producing uneven cuts, check if the blades are properly aligned. Adjust the blade alignment according to the manufacturer’s instructions.

Paper Jams: If the paper gets stuck in the machine, turn off the power and carefully remove the jammed paper. Make sure to follow the proper procedure outlined in the machine’s manual to avoid damaging the machine or injuring yourself.

Motor Malfunctions: If the machine’s motor is not running or is making unusual noises, check if the power supply is connected correctly. If the issue persists, contact the manufacturer or a professional technician for assistance.

Regular maintenance and prompt troubleshooting can prolong the lifespan of your commercial paper cutting machine and ensure its optimal performance.

Conclusion: The Future of Commercial Paper Cutting Machines

The commercial paper cutter stands as a pivotal innovation within the paper processing sector, transforming operational efficiency through its combination of speed, precision engineering, and automated systems. For enterprises managing substantial paper volumes, it has transitioned from a convenience to an indispensable asset, with ongoing technological progress promising even greater capabilities.

Procuring such a machine represents a strategic acquisition, delivering measurable gains in workflow throughput, cut consistency, and operational safety standards. A comprehensive understanding of its mechanics, the various models on the market, and key selection criteria is fundamental to leveraging its full capacity and advancing your production standards.

Therefore, for any business seeking to modernise laborious, time-intensive manual cutting processes, investing in a commercial paper cutter is a prudent decision. This commitment yields significant long-term returns—not only in time and cost savings but also in the markedly enhanced quality and efficiency of your output.