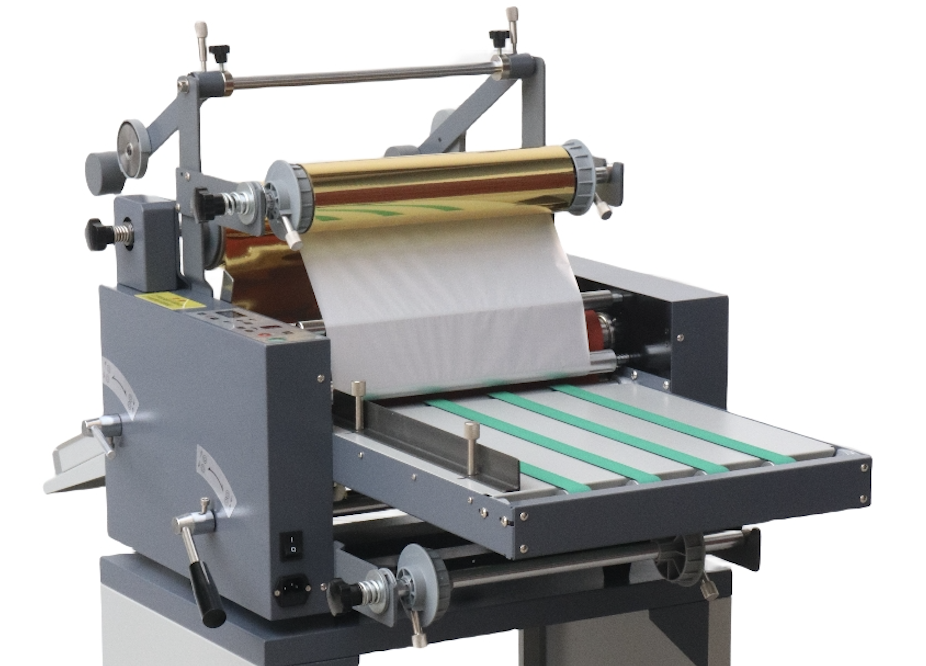

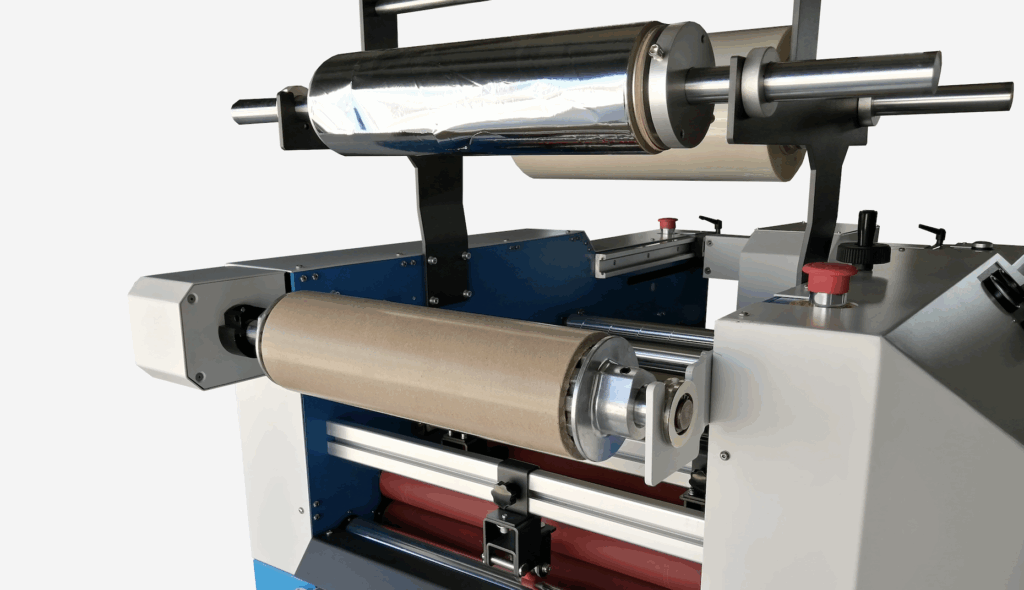

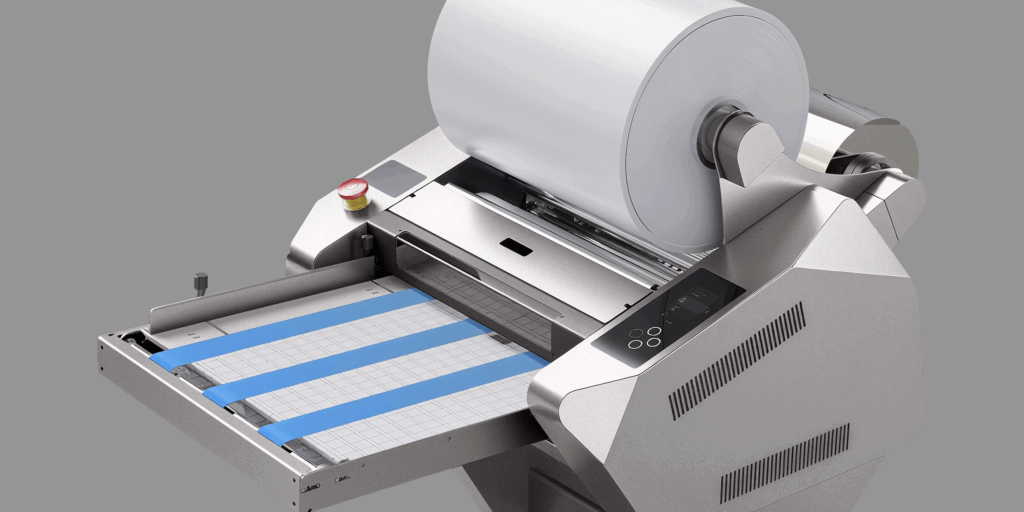

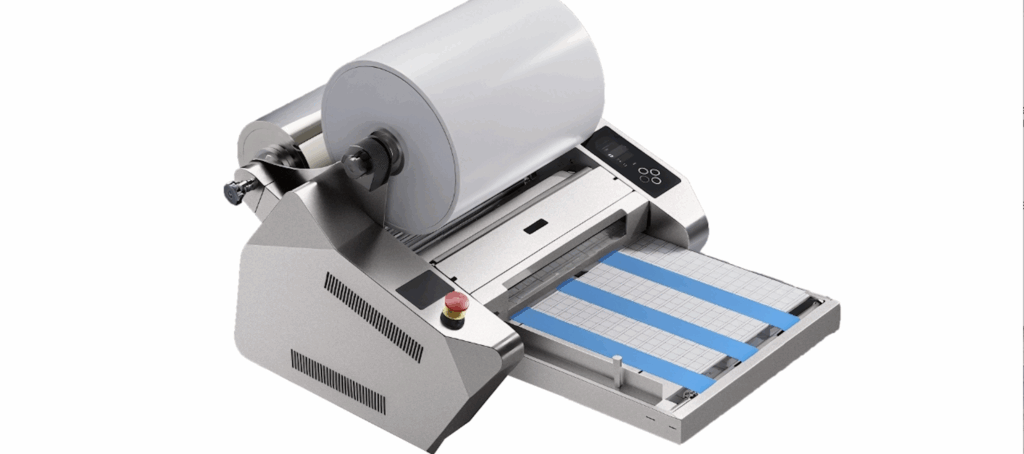

Foil Laminating machine

In today’s competitive marketplace, establishing a distinctive and premium brand identity is essential. Foil laminating, with its refined metallic sheen and sophisticated finish, serves as a powerful tool for brand enhancement. This specialised finishing technique can elevate product packaging and printed materials, creating immediate visual and tactile appeal that resonates with your audience and differentiates your offerings.

A brand’s visual presentation directly communicates its values and perceived quality. Integrating hot foil stamping or cold foil lamination into your branding strategy delivers a notable visual impact. This deliberate investment in superior finish quality not only captures attention but also fosters an association with luxury and craftsmanship, ultimately strengthening brand perception and consumer engagement.

The benefits of foil laminating for branding

Incorporating foil finishing into your branding strategy delivers significant competitive advantages. Primarily, it elevates the perceived value of your products. The lustrous metallic sheen conveys an immediate impression of quality and exclusivity, positioning your offering within a premium tier. This enhanced perception directly influences purchasing decisions, fostering greater customer loyalty and driving sales performance.

Furthermore, foil application dramatically increases shelf and stand-out appeal. The reflective surface actively captures light and attention in both physical retail and digital settings, ensuring your packaging stands out amidst competing products. This visual distinction is crucial for attracting potential customers and encouraging closer inspection.Moreover, it provides a distinctive tactile dimension. The smooth, polished finish adds a sophisticated textural element to your packaging, enriching the customer’s unboxing experience. This positive sensory interaction fosters a memorable connection with your brand, reinforcing perceptions of quality and creating a lasting, favourable impression.

Foil laminating techniques and options

Within foil finishing, two primary techniques exist to meet distinct brand and production requirements: hot foil stamping and cold foil transfer. Hot foil stamping employs a custom-heated die to permanently impress the foil onto the substrate, yielding an exceptionally crisp, tactile result ideal for intricate logos, fine text, and luxury applications where precision and a raised finish are paramount.

Conversely, cold foil transfer utilises a UV-curable adhesive printed onto the material, to which the foil layer bonds before being laminated. This process allows for high-speed application, excellent registration with other print techniques like offset, and greater flexibility for multi-colour or large-area coverage, offering a cost-effective metallic effect.

Selecting the optimal foil involves assessing several key properties:

- Colour & Finish: A vast palette extends beyond standard gold and silver to include pigments, holographics, and matte or glossy finishes.

- Durability & Compatibility: The foil must be engineered for the specific substrate (e.g., paper, card, plastic) and any subsequent processes (like varnishing or folding) to ensure rub resistance and longevity.

- Adhesion Quality: Consistent, complete bonding without flaking or cracking is critical for a professional result.

Consulting with a specialist finisher to test foils on your actual material is the most reliable method for achieving the desired aesthetic and functional quality.

How foil laminating can elevate your brand’s image

Integrating foil finishing into your brand’s visual identity operates on multiple strategic levels to fundamentally enhance perception. Primarily, it confers an immediate sense of prestige and meticulous craftsmanship. The distinctive lustre and tactile quality are intrinsically associated with luxury, enabling brands to elevate their market positioning and appeal to discerning consumers.

This process also unlocks significant creative and customisation potential. With an extensive spectrum of available foils—including metallic, pigmented, matte, gloss, and holographic finishes—brands can execute unique designs that precisely embody their identity. This versatility ensures standout shelf presence and fosters a memorable, cohesive brand experience.Critically, the application of foil signals a tangible commitment to quality. The technical precision required for flawless execution communicates an investment in superior materials and attention to detail. This not only reinforces the product’s perceived value but also builds deeper consumer trust and brand loyalty, as customers associate the refined finish with overall excellence and reliability.

Choosing the right materials for foil laminating

The selection of an appropriate substrate is fundamental to the success of any foil application, as the material directly influences the finish’s brilliance, adhesion, and durability. Optimal results are achieved by pairing the foil process—hot stamping or cold transfer—with a compatible, high-quality base material.

Guidelines for Substrate Selection

For optimal foil adhesion and visual impact, the substrate must have a smooth, consistent, and non-porous surface. The choice depends largely on the intended application and desired aesthetic.

Paper and Cardstock

- Coated Stocks: Gloss or matt coated papers and cards are ideal, as their sealed surface allows for maximum foil adhesion and reflectivity. A medium to high grammage (gsm/weight) is recommended to provide structural integrity, prevent warping under heat (for hot foil), and convey a premium tactile quality.

- Uncoated Stocks: While possible, foil application on uncoated, porous papers yields a softer, more muted finish. This can be a deliberate aesthetic choice for a vintage or textured look.

Synthetic Materials (Plastics & Acetates)Specialised foils and adhesives are required for synthetic substrates like PVC, PET, or polypropylene. Surface energy is critical; materials often require pre-treatment (such as corona treatment) to ensure proper foil adhesion. Always consult your foil supplier to match the foil type and adhesive system precisely to your chosen plastic.

Critical Pre-Production Step: Testing

Regardless of material, conducting a comprehensive pre-production test on the exact substrate with the selected foil is non-negotiable. This verifies compatibility, evaluates durability (including rub and scratch resistance), and ensures the final result meets your quality and aesthetic specifications.

Foil laminating vs other branding techniques

Within the spectrum of brand finishing techniques, foil application provides distinct advantages that secure its prominence for premium presentation. Unlike conventional flat printing, it delivers a tangible, light-reflective quality that introduces depth and a dynamic visual appeal unattainable with ink alone.

While techniques like embossing create texture, foil finishing offers superior design flexibility and precision. It can be applied to specific, intricate areas of a design—from fine typography to detailed logos—allowing for targeted highlights and complex patterns that dramatically enhance brand assets.

Moreover, it represents a strategic and cost-effective investment for brand elevation. By collaborating with an experienced finisher, businesses can access this high-impact technology without major capital expenditure on specialised machinery. This accessibility enables brands of all scales to utilise a finish that perceptibly elevates product value and market presence.

Conclusion: Harnessing the power of foil laminating for your brand success

The strategic application of foil finishing serves as a powerful differentiator in a saturated marketplace, directly enhancing brand perception and consumer engagement. Its signature metallic sheen elevates the perceived value of products and creates immediate shelf impact, forging a memorable and positive impression that extends the customer experience beyond the initial purchase.

This technique offers extensive creative scope for brand expression. Whether executing a minimalist, contemporary design or a detailed, classic motif, custom metallic effects can be precisely aligned with brand identity. Successful realisation depends on two key factors: selecting compatible, high-quality substrates to ensure optimum foil adhesion and visual brilliance, and partnering with an expert finisher capable of delivering consistent, superior results.

By integrating foil finishing into your branding strategy, you transform packaging and print materials into a tangible visual asset. This investment not only distinguishes your offerings but also communicates a commitment to quality, craftsmanship, and distinctive style.