Paper Creasing Machine

A professional paper creasing machine is an essential investment for any business seeking to eliminate the inefficiencies and inconsistencies of manual folding. By performing precise, controlled creasing on paper stocks, these machines prevent unsightly cracks and fibres from appearing along fold lines, ensuring a flawless, professional finish for brochures, greeting cards, and presentation materials.

Selecting the correct model is crucial for optimising your workflow. This guide outlines the core considerations to help you navigate the available options, from high-volume digital creasers to versatile manual systems, ensuring your choice enhances productivity and elevates the quality of your final product. Key decision factors include your typical material types, required throughput, and the necessary creasing complexity.

The importance of paper creasing machines in business

In commercial printing and document finishing, manual folding is often a labour-intensive and inconsistent process. A professional creasing machine provides an engineered solution, creating precise, sharp creases that ensure a flawless, professional finish for folded materials.

The primary operational advantage is a significant reduction in processing time. By automating the creasing and folding sequence, these machines handle multiple sheets in a single pass, eliminating the slow, repetitive task of manual alignment and folding for each item individually.

Furthermore, they guarantee exceptional consistency. Hand-folding frequently results in misaligned or uneven creases, which detract from a document’s perceived quality. A creasing machine delivers perfectly uniform results every time, producing crisp, clean folds that enhance the polished appearance of brochures, invitations, and marketing materials. This combination of speed and precision is fundamental for maintaining both high output and professional standards.

Different types of paper creasing machines

Paper creasing machines are categorised into distinct operational types to suit varying production volumes and finishing requirements. The three primary classifications are manual, electric, and hydraulic systems, each offering a different balance of control, speed, and force.

Manual creasing machines require full operator control for feeding and activating the creasing mechanism. Representing the most economical entry point, they are well-suited for low-volume workshops, studios, or offices with intermittent needs.

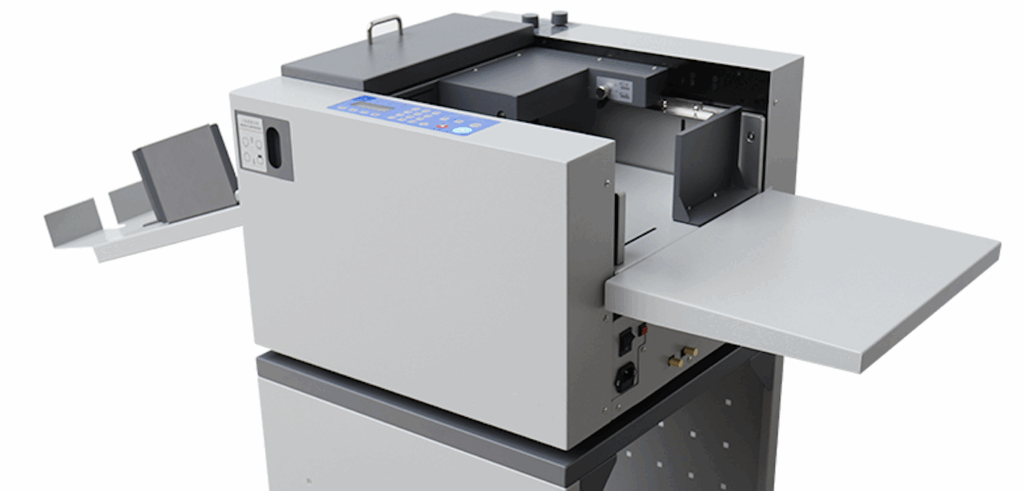

Electric creasing machines provide automated operation, significantly increasing throughput for consistent, repeated tasks. Often featuring adjustable creasing depth and programmable settings, they offer enhanced flexibility and are ideal for medium to high-volume commercial print environments requiring efficiency and repeatable precision.

Hydraulic creasing machines deliver the highest level of force for industrial applications. Utilising hydraulic pressure, they produce exceptionally crisp, clean creases on heavy stocks or complex folds. These robust systems are designed for continuous, high-volume production in large-scale printing and packaging operations where uncompromising professional results are essential.

Factors to consider when choosing a paper creasing machine

Selecting an optimal paper creasing machine requires a methodical evaluation of technical specifications, operational needs, and long-term value. A strategic assessment based on the following core factors will guide a sound investment decision.

Technical Performance & Versatility First, analyse the machine’s creasing and perforation capabilities against your specific project requirements. Assess whether it handles basic folds or more complex tasks like micro-perforations or intricate creasing patterns. Key features such as adjustable creasing depth and tool-free rule changes are essential for adapting to different paper stocks and achieving a professional finish.

Operational Throughput & EfficiencyThe machine’s rated speed and sheet capacity directly impact workflow productivity. For environments with high-volume output, a model designed for faster, continuous operation is crucial to maintain efficiency and meet production deadlines without creating bottlenecks.

Build Quality & Long-Term Reliability Durability is paramount. Prioritise machines constructed with industrial-grade components and a robust frame to withstand regular use. Investigate the manufacturer’s reputation for reliability and the quality of their customer and technical support, as these factors significantly influence long-term operational uptime.

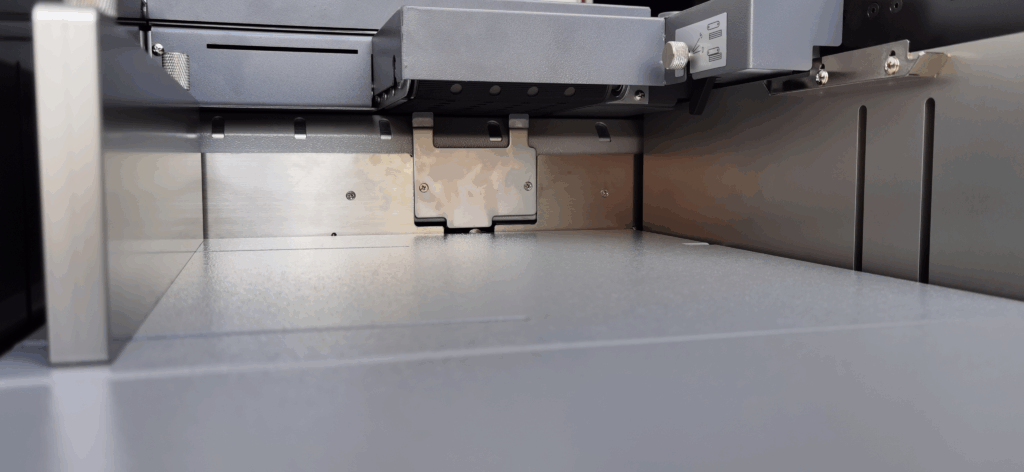

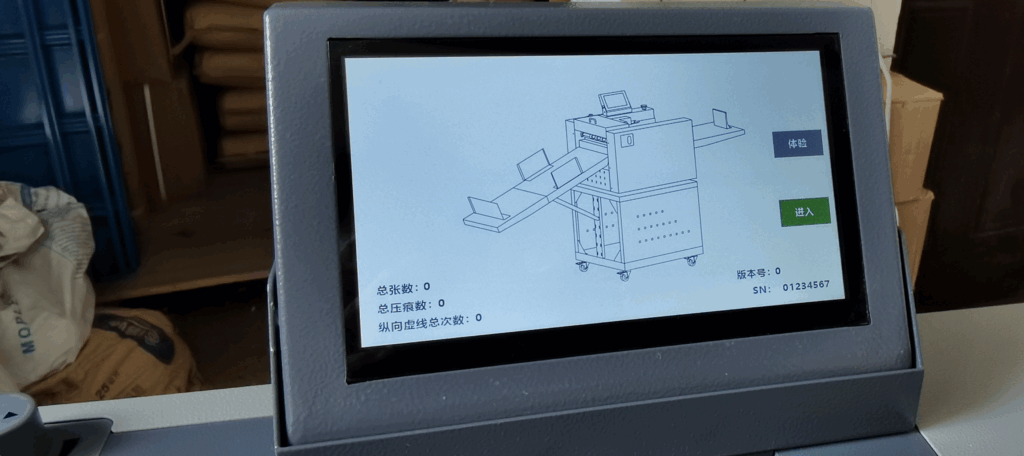

Ergonomics & IntegrationAn intuitive control interface and simplified maintenance protocols reduce operator training time and minimise errors. Consider the machine’s physical footprint and how seamlessly its setup and routine care integrate into your existing workflow.

Total Cost of Ownership Establish a clear budget that accounts for the complete investment, including the purchase price, ongoing maintenance, and potential tooling or accessory costs. While initial cost is a factor, the primary focus should be on securing a machine that delivers the best combination of performance, durability, and functionality for your investment, ensuring strong returns over its service life.

Understanding the creasing capabilities and features

Selecting an industrial creasing machine requires a detailed understanding of its technical capabilities, as these directly determine the quality, versatility, and efficiency of your finishing output. Key functionalities to assess include:

1. Fold and Perforation Diversity Beyond basic linear creases, evaluate the machine’s ability to execute specialized operations. This includes micro-perforations for tear-off sections, and intricate double or parallel scores for complex folded items like pocket folders or multi-panel brochures.

2. Precision Depth Adjustment. A critical feature is micrometer-adjustable creasing depth. This allows precise calibration for different paper weights (gsm) and finishes—ensuring a sharp, clean fold on heavy card stock without cracking, while applying a lighter touch for delicate text papers.

3. Productivity Enhancements: Batch Processing & Memory For high-volume work, batch counters automate the processing of set quantities. Furthermore, digital memory functions allow operators to save and instantly recall precise settings for different job profiles (e.g., A4 letter fold on 200gsm card). This eliminates manual recalibration, guaranteeing consistency and drastically reducing setup time between jobs.

These core capabilities—versatility in finish, precision in execution, and automation in workflow—enable a single machine to handle a wide range of professional tasks, from simple leaflets to complex packaging, ensuring flawless results and optimal throughput.

Evaluating the speed and productivity of the machine

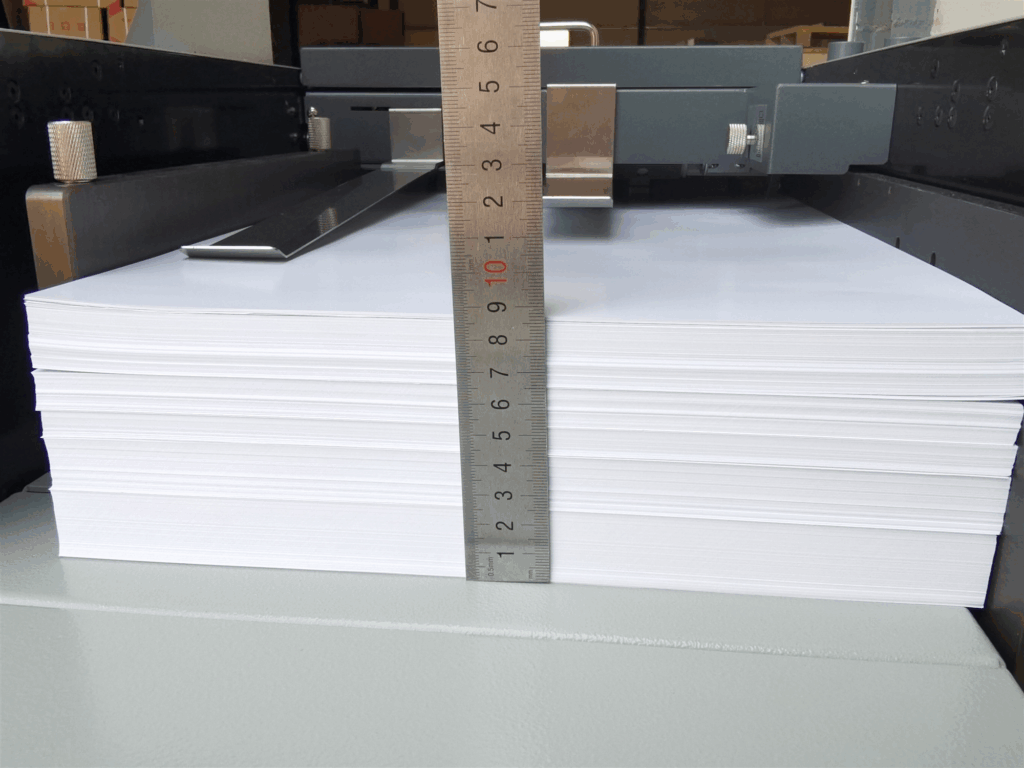

The operational throughput of a creasing machine is a critical performance metric for any commercial printing or finishing environment. Evaluating this effectively requires analyst both the machine’s rated speed (typically in sheets per minute) and its input capacity (the number of sheets the feeder can hold). A higher capacity directly reduces the frequency of manual reloading, thereby maximise continuous production time and overall productivity.

It is essential to understand that throughput is highly dependent on substrate specifications. The machine’s optimal speed for standard 100gsm paper will differ from its handling of heavy 350gsm card stock or textured materials. Therefore, the most efficient choice is often a model with variable speed control, allowing operators to calibrate the feed rate to the specific material being processed. This ensures that speed does not compromise the quality of the crease, preventing issues like paper jam or imprecise folding on delicate or heavy weight stocks.

Ultimately, true productivity is measured by consistent, high-quality output per hour. The ideal machine balances a high maximum speed with the robust mechanics and precise control needed to maintain that speed across your most common material types, minimizing both cycle time and waste.

Assessing the durability and reliability of the machine

Evaluating the long-term durability and operational reliability of a paper creasing machine is a fundamental aspect of the procurement process. The construction quality serves as the primary indicator of longevity; prioritise models engineered with a heavy-duty steel chassis and industrial-grade components designed to endure the rigours of continuous commercial use.

Beyond physical inspection, independent verification is crucial. Scrutinise verified customer testimonials and professional case studies to gain insight into real-world performance, common maintenance points, and potential limitations over time. Furthermore, investigate the manufacturer’s reputation for product support, including the availability of technical assistance, spare parts, and comprehensive warranty terms. A reputable supplier provides essential security, ensuring minimal operational disruption throughout the equipment’s service lifecycle.

Conclusion: Making an informed decision for your business

Selecting the optimal paper creasing machine is a critical decision that directly influences the efficiency and quality of your document finishing workflow. A methodical evaluation, focusing on core performance specifications, build quality, and operational costs, will guide you to an investment that delivers sustained value and enhances your output.

Integrating a professional-grade creasing system streamlines production, guarantees precision, and elevates the finish of folded items, from brochures to presentation folders. Whether your operation necessitates a manual, electric, or hydraulic model, prioritizing a machine with the precise capabilities for your typical substrates and fold types is essential.

Ultimately, this equipment represents a strategic investment in your operational proficiency. Dedicating time to thorough research and comparison ensures your chosen model not only meets immediate demands but also supports consistent, professional results that strengthen your brand’s reputation for quality.