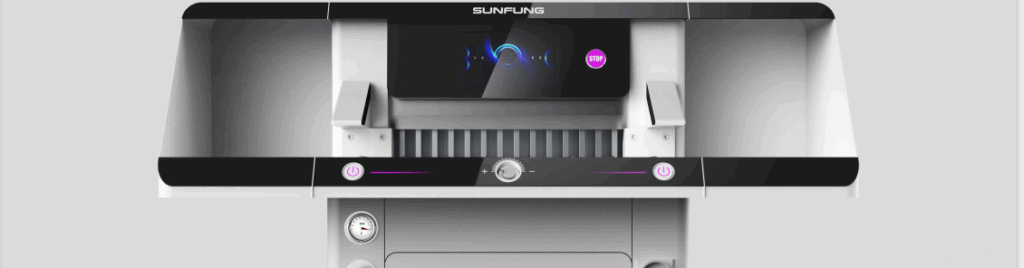

Introduction to Hydraulic Cutter

Hydraulic Cutters have transformed methodologies for slicing through diverse substances, offering enhanced speed, accuracy, and efficiency. For both the DIY enthusiast and the industrial worker, these tools significantly reduce labor and time while ensuring superior outcomes. This detailed overview will explore all essential aspects of Hydraulic Cutter technology, applications, and selection criteria.

How Hydraulic Cutter Work

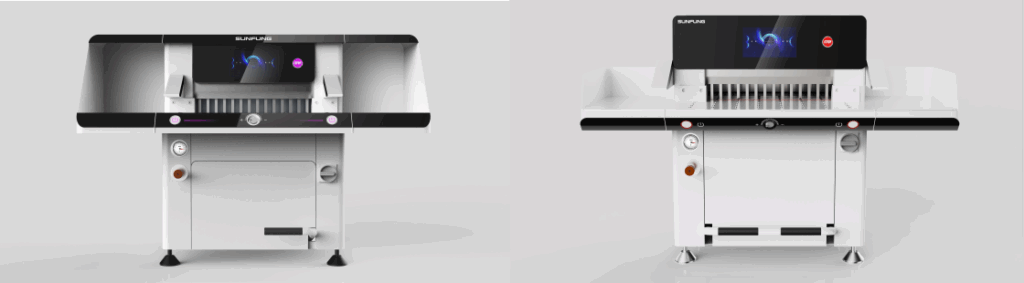

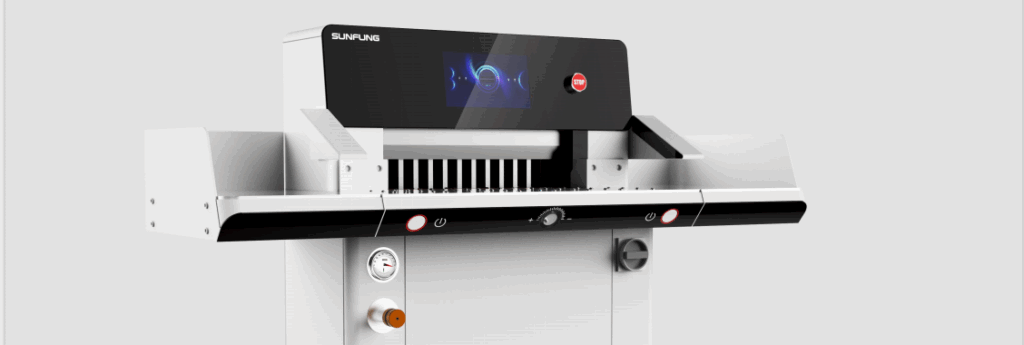

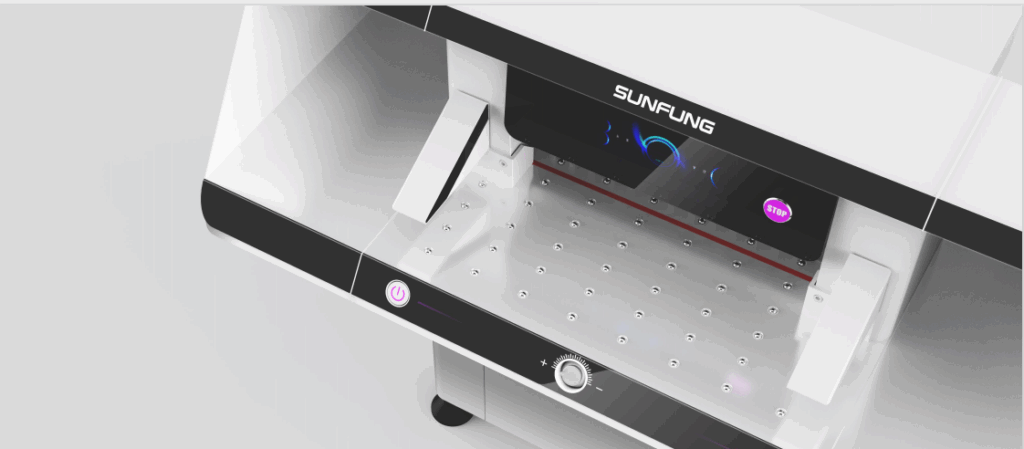

Hydraulic Cutters function by employing precision blades driven by hydraulic system. This mechanism enables them to cleanly slice through an extensive array of substances, from pliable textiles and paper to resilient synthetics like vinyl and leather, as well as softer, thin-gauge metals. The motor transmits consistent force to the cutting edge, guaranteeing smooth and exact incisions. Depending on their design, these tools can be operated via manual control or sophisticated digital programming interfaces.

Hydraulic Cutter Benefit

Utilizing an Hydraulic Cutter delivers substantial benefits that justify its initial cost. A primary advantage is the dramatic acceleration of the cutting workflow, enabling task completion in considerably less time compared to conventional manual techniques. Furthermore, these tools deliver exceptional accuracy, producing consistently neat and exact cuts, which is indispensable for detailed or complex artistic work.

The adaptability of the Hydraulic Cutter stands out as another major advantage. By selecting appropriate blades and adjusting configurations, it can process a diverse spectrum of materials, catering to numerous applications. These devices are also designed to be intuitive, demanding little physical exertion. Regardless of skill level, operators can master the controls with ease and attain finishes of a professional standard.

Different Hydraulic Cutters

There are several types of Hydraulic Cutters available in the market, each with its own set of features and capabilities. The most common types include:

Die-cutting machines: These machines use metal dies to cut out specific shapes from materials such as paper, fabric, and foam. They are perfect for creating custom cards, scrapbooking, and other craft projects.

Vinyl cutting machines: Designed specifically for cutting vinyl, these machines are ideal for creating decals, stickers, and signage. They can also be used for heat transfer projects, such as creating custom t-shirts.

Computerized cutting machines: These advanced machines are controlled through software, allowing you to create intricate designs and patterns. They are commonly used in the textile and fashion industries for cutting fabric and leather.

What to consider when purchasing an Hydraulic Cutter

Prior to selecting an Hydraulic Cutter, evaluating several vital factors will guide you to the most suitable model for your applications:

Material Capacity: Assess the density and dimensions of the substances you intend to process. This determines the necessary power and bed size of the equipment.

Cutting Tool Versatility: Investigate the range of compatible blades. Access to various specialized blades significantly expands the machine’s utility for different projects.

Operational Interface: Prioritize an intuitive design. Decide between manual operation or a digital control system based on your comfort level and project complexity.

Software Integration: For digital models, verify compatibility with your preferred design programs. This is crucial for importing and executing custom patterns, ensuring a seamless workflow.

Budget Range: Establish a financial framework and compare models within it. Consider not only the initial purchase price but also long-term value, as advanced features often justify a higher investment.

Tips for use Hydraulic Cutter Effectively

To optimize the performance and longevity of your Hydraulic Cutter, adhering to these practical guidelines is highly recommended:

Consult the Documentation: Thoroughly review the user guide to gain complete understanding of the device’s functionalities, operational parameters, and essential safety measures.

Begin with Fundamentals: New users should initiate their practice with straightforward tasks. This builds proficiency and provides a practical understanding of the tool’s range.

Conduct Preliminary Trials: Always execute test cuts on sample material before commencing your actual project. This step verifies that blade selection and machine settings are correctly calibrated for a perfect finish.

Implement Routine Maintenance: Consistently clean the cutting mechanism and the unit itself to remove accumulated residue. This prevents operational issues and preserves the Hydraulic Cutter’s precision and efficiency.

Invest in Superior Blades: Utilizing high-grade, specialized cutting blades is crucial. They not only produce sharper, cleaner results but also reduce wear on the machine, thereby extending its useful life.

Hydraulic Cutter Maintenance Guide

To ensure your Hydraulic Cutter remains in excellent working order, regular upkeep is vital. Here are some straightforward steps to include in your routine:

Keep Blades Clean: Following each use, gently wipe the blades with a soft cloth or brush to clear away any leftover fragments. This stops material from building up, which can make cuts less precise.

Lubricate Moving Components: Apply a little machine oil to any moving parts, as the manufacturer guides, for smooth and effortless operation.

Store with Care: When the tool is not in use, keep it in a dry, clean place. Using a protective cover will shield it from dust and accidental knocks.

Check and Replace Parts: Regularly inspect the blades and other parts for wear. Switching out any that are dull or nicked straight away will help maintain the quality of your work and the machine’s performance.

Hydraulic Cutter Applications

An Hydraulic Cutter offers extensive potential across a wide variety of creative and professional tasks. Key applications include:

Crafting and Stationery: Produce elaborate patterns, decorative edges, and custom shapes for handmade cards, memory books, and papercrafts.

Interior Personalisation: Craft vinyl decals or precise stencils to add unique designs to walls, furniture, and household items.

Apparel and Soft Furnishings: Utilise digital Hydraulic Cutters for accurately slicing fabrics and leathers in the making of clothing, bags, and upholstery.

Needlework and Patchwork: Efficiently prepare material pieces for quilting, appliqué, and garment construction, streamlining the sewing process.

Commercial Signage: Design and produce professional vinyl lettering, logos, and graphics for promotional displays and business signage.

Conclusions

Hydraulic Cutters have established themselves as essential instruments for hobbyists, home improvers, and trade professionals. Their capacity for delivering unmatched precision across diverse substances has transformed numerous fields. Gaining insight into their operation, advantages, and available models empowers you to select the most appropriate device for your requirements. Key purchasing considerations encompass material compatibility, accessory versatility, user interface, digital integration, and overall value. With diligent upkeep, your Hydraulic Cutter will reliably produce high-quality outcomes over an extended period.

Discover the potential of this technology and elevate your creative projects. From experienced artisans to those beginning their journey, an Hydraulic Cutter serves as a dependable partner in materialising concepts. Embrace the innovation and explore the vast opportunities it presents for your work.