Heavy Duty Laminator Machine: Benefits

For businesses and institutions where document durability and presentation are paramount, professional-grade laminators are indispensable. Standard desktop units often prove inadequate for demanding, high-volume tasks. Industrial heavy-duty laminating machines provide the robust performance necessary for consistent, commercial-quality finishing, transforming a routine task into a reliable pillar of professional output.

These systems deliver distinct operational advantages, including the ability to process wider formats and greater material thicknesses with flawless, bubble-free adhesion. Engineered for continuous operation, they significantly enhance throughput and material versatility, supporting everything from protective educational resources to durable point-of-sale displays. Investing in an industrial laminator represents a strategic upgrade, ensuring impeccable results, improved workflow efficiency, and a stronger, more professional finish for all your laminated materials.

Durability and Versatility

A defining characteristic of commercial-grade laminators is their exceptional robustness. Engineered for resilience with premium components, they are constructed to endure the rigours of continuous, high-volume operation. This robust design enables them to consistently process more demanding applications, including wider format items, thicker substrates, and high-yield project runs that would compromise standard models. The capacity to reliably finish everything from instructional posters to large-format displays translates into a dependable, long-term asset. This inherent durability offers a superior return on investment, providing a consistently reliable finishing solution for professional environments.

Professional Results Every Time

A further critical advantage of professional laminating systems is their capacity to produce flawlessly consistent, professional finishes. Equipped with sophisticated controls for precise temperature regulation and variable processing speed, these machines allow for exact calibration to suit specific material types and project requirements. This ensures optimal adhesion and a pristine finish across a wide spectrum of substrates, from delicate archival papers to robust display boards.

Moreover, integrated safety mechanisms, such as automatic thermal shut-off, protect both the equipment and the materials from potential heat damage during operation. This combination of advanced technical control and built-in protection guarantees reliable, high-quality outcomes for every lamination task, providing complete confidence in the final product’s durability and appearance.

Time and Cost Efficiency

Professional laminating systems are engineered for maximum operational throughput, representing a sound investment for environments with substantial finishing volumes. A key efficiency feature is their rapid start-up capability, reaching optimal operating temperature swiftly to minimise preparatory delays. Furthermore, these machines offer higher processing speeds, significantly accelerating project completion times. This enhanced efficiency directly translates to reduced labour costs and greater daily output. By streamlining the lamination workflow, a heavy-duty system allows personnel to reallocate time to other core tasks, thereby elevating overall department productivity and improving return on investment.

Types of heavy duty laminator machines

Professional laminating systems are categorised into distinct types, each engineered for specific operational demands and material requirements. Selecting the correct model is fundamental to achieving optimal results and workflow efficiency. The primary classifications include thermal (heated roll) laminators, cold laminators, wide-format roll systems, and pouch laminators, with industrial variants designed for continuous, high-volume throughput.

Pouch Laminators

Pouch laminators are widely utilised across educational, office, and commercial environments due to their straightforward operation and adaptability. The process involves sealing a document within a pre-formed film pouch and feeding it through heated rollers, which activate the adhesive to create a durable, encapsulated finish.

Their principal advantage lies in their flexibility with various standard pouch sizes, accommodating items from identification cards to A3-sized sheets. Commercial-grade models enhance this versatility with precision temperature controls, allowing operators to adjust settings for different material weights and film thicknesses, thereby ensuring optimal results for everything from delicate paper to cardstock.

For consistent, high-volume output, heavy-duty pouch laminators offer superior durability, faster throughput, and enhanced features such as separate top and bottom heat settings for a perfect seal, making them a reliable choice for professional applications.

Roll Laminators

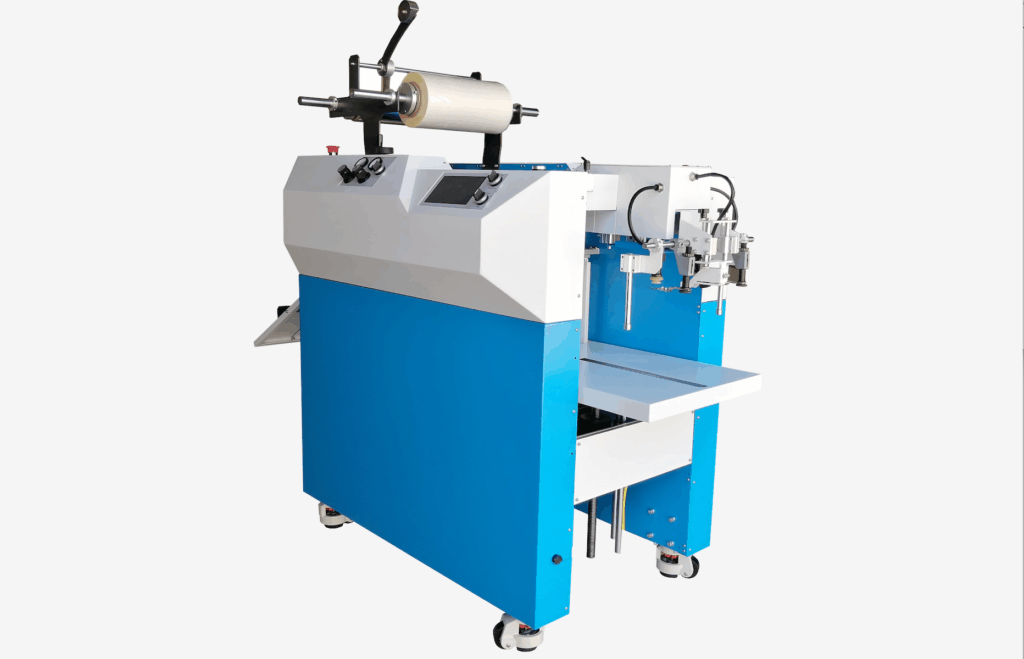

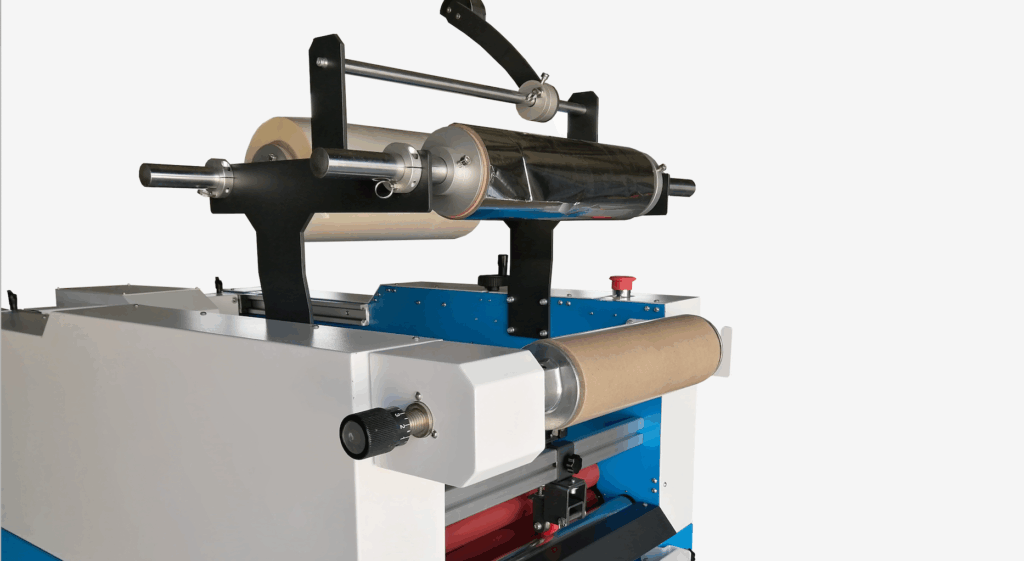

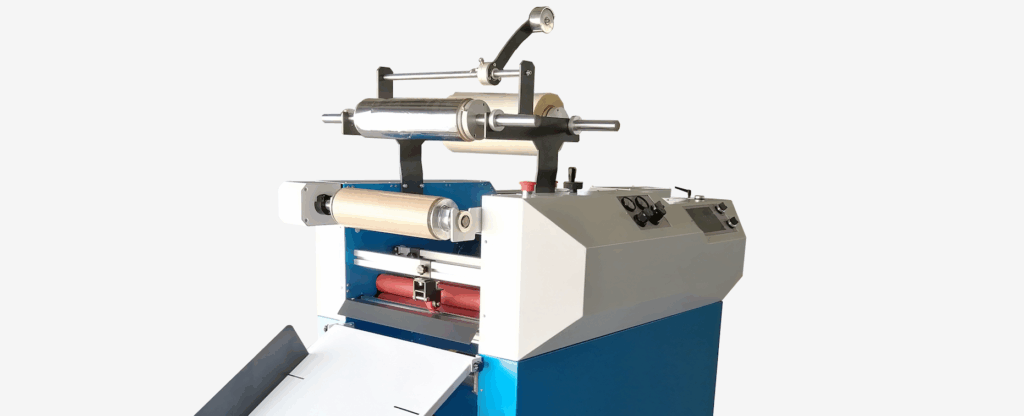

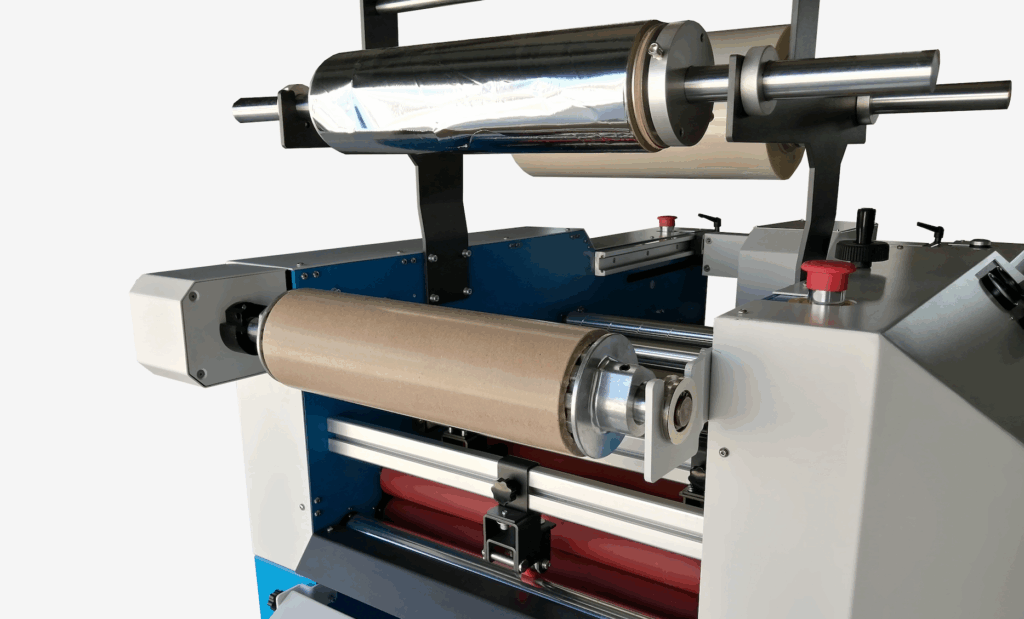

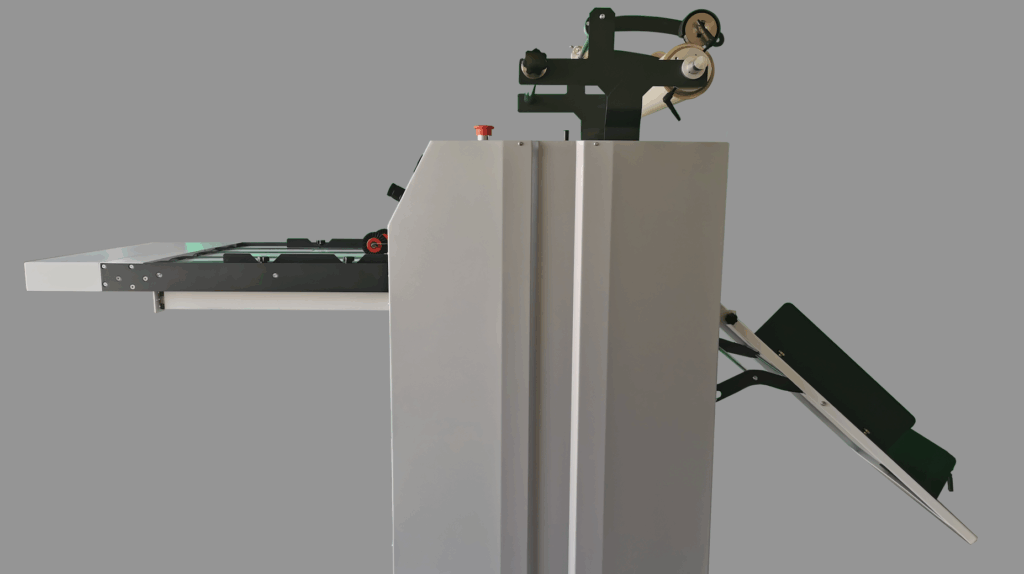

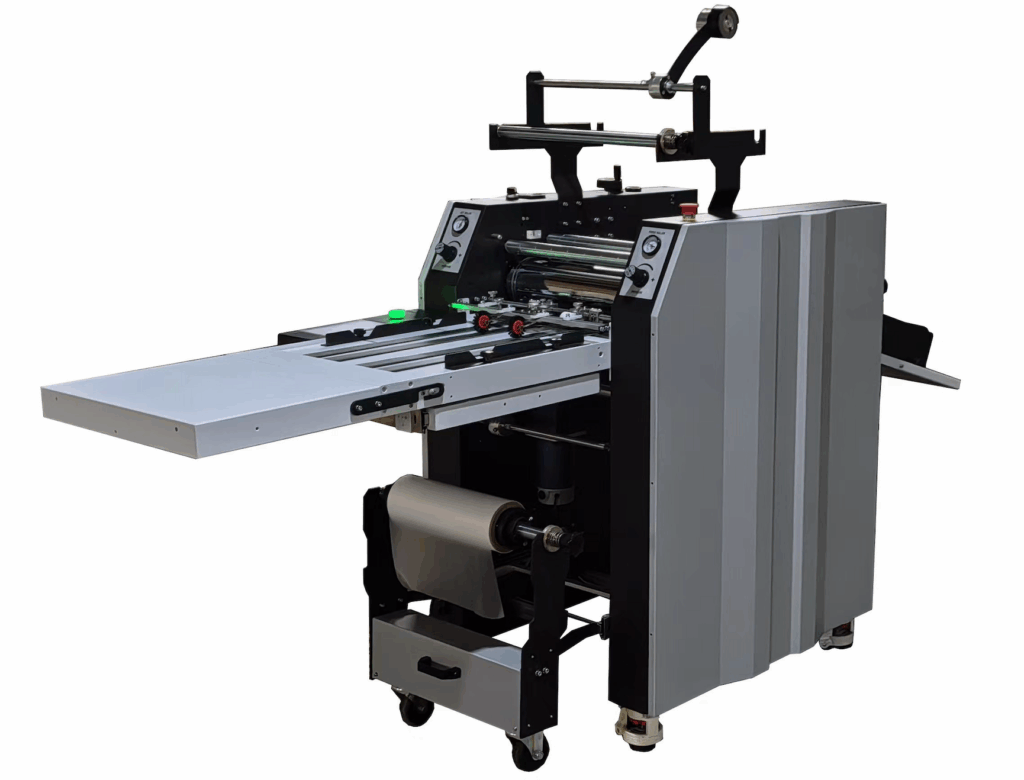

Roll laminators, or hot film systems, represent the industrial-grade solution for high-volume and wide-format applications. Unlike pouch-based units, they utilise continuous rolls of film, enabling them to process materials of considerable length and width, such as banners, posters, and exhibition graphics. This makes them essential equipment within commercial print, advertising, and sign-making sectors.

Their design prioritises continuous throughput, offering significantly faster operational speeds than standard models. Professional units provide precise control over the lamination process through adjustable thermal settings and variable speed drives, allowing operators to perfectly calibrate for different film and substrate types. This combination of scale, speed, and technical control makes the roll laminator indispensable for demanding, large-scale finishing projects.

Cold Laminators

Precisely. Cold laminators utilise a distinct technology, employing pressure-sensitive adhesive films that bond to the substrate without the application of heat. This makes them the indispensable choice for preserving and protecting heat-sensitive materials—such as solvent-based inkjet prints, certain photographic media, delicate artwork, and documents with thermal inks or plastic components—where traditional thermal methods would cause damage.

Their application is critical in sectors like fine art reproduction, professional photography, and archival projects. Furthermore, they are exceptionally well-suited for large-format items including architectural blueprints, engineering maps, and vehicle graphics, providing a durable, protective finish without risk of distortion or adhesive failure from heat exposure. This technology ensures the integrity and longevity of sensitive originals.

Wide-Format & Industrial laminators

These robust machines handle very wide media (often exceeding 1.5 metres) and are built for continuous, unattended operation. They are indispensable for large-format graphics, exhibition displays, and industrial applications requiring extreme durability, often featuring advanced tension controls and multi-zone heating.

Understanding these core types—thermal for general use, cold for sensitive media, pouch for sealed items, and wide-format for large-scale projects—enables a strategic investment that aligns precisely with your specific laminating needs, material types, and production volume.

Factors to consider when choosing a heavy duty laminator machine

Selecting a commercial-grade laminating system is a significant procurement decision, given the diverse range of models and specifications available. A methodical evaluation based on core operational and technical criteria is essential to identify the equipment that will deliver optimal performance, reliability, and return on investment for your specific application. The following key factors provide a structured framework for your assessment.

Laminating Speed

The operational throughput, or laminating speed, of a machine is a critical specification directly affecting workflow capacity. For environments with high-volume demands, selecting a unit with a superior processing rate is essential for maintaining productivity and meeting deadlines.

It is crucial, however, to calibrate the feed rate to the specific material being processed. An excessively high speed can prevent the film adhesive from bonding correctly or the heat from transferring uniformly, potentially resulting in substandard finishes such as poor adhesion, bubbling, or wrinkles.

Therefore, the optimal choice involves selecting a machine that offers a variable speed control. This feature allows the operator to balance swift throughput for simple jobs with a slower, more precise setting for delicate or heavyweight materials, ensuring both efficiency and consistently professional, high-quality results. Prioritising a model with this flexibility future-proofs your investment against a diverse range of project requirements.

Laminating Width

The maximum laminating width is a fundamental specification that dictates the range of projects a machine can handle. It is essential to select a model whose width capacity comfortably exceeds the dimensions of your most commonly processed items. For standard office documents, an A3-capable machine typically provides sufficient versatility.

For businesses requiring the finishing of wide-format materials—such as exhibition posters, banners, or architectural plans—investing in a professional wide-format roll laminator with a larger throat width becomes necessary. It is important to note that increased mechanical capacity often correlates with a higher initial investment. Therefore, a careful assessment balancing your typical document sizes, occasional large-format needs, and budget parameters is crucial to securing a machine that offers both immediate utility and long-term value without overspending on unused capability.

Adjustable Temperature Settings

Precise thermal control is a fundamental feature of any professional laminating system, as optimal adhesion varies significantly with material type. The ability to calibrate temperature settings is therefore essential, allowing the operator to tailor the process to specific substrates. Delicate items, such as certain photographs or lightweight papers, often require lower heat to prevent warping or ink smearing, whereas thicker stocks or synthetic materials may need higher temperatures to ensure a complete, durable bond. Selecting a machine with responsive, adjustable thermal settings guarantees both the protection of sensitive originals and the effective finishing of more robust items, ensuring consistently high-quality results across a diverse workload.

Automatic Shut-off

A built-in automatic shut-off mechanism is an essential safety and preservation feature in commercial-grade laminating systems. Primarily, it prevents overheating during extended idle periods by powering down the machine after a preset interval of inactivity, thereby eliminating a key risk to both sensitive documents and the unit’s internal components. This intelligent thermal management not only safeguards your materials but also contributes significantly to the equipment’s long-term operational reliability and service life. When evaluating systems, prioritising this feature ensures enhanced safety, protects your output quality, and represents a prudent consideration for long-term asset management.

Ease of Use and Maintenance

Operational simplicity and straightforward upkeep are vital considerations when selecting a heavy-duty laminating system. An intuitive control panel with clearly labelled functions and comprehensible operational guidelines significantly reduces the learning curve for new users and minimises setup errors, ensuring efficient workflow from the outset. Alongside ease of use, a realistic assessment of the machine’s maintenance protocol is essential. A system requiring only routine, simple tasks—such as regular cleaning of rollers and basic safety checks—is ideal for sustained performance. Prioritising a laminator that aligns with your operational capacity for maintenance ensures not only consistent, high-quality results but also long-term reliability and value from your investment.

How to use a heavy duty laminator machine effectively

Employing a heavy-duty laminator to its full potential requires meticulous technique and careful operation. To consistently achieve professional results and ensure the longevity of the equipment, adhering to best practice guidelines is essential. While specific procedures should always follow your model’s manual, the following universal principles form the foundation for effective use.

Read the User Manual

Adhering to the manufacturer’s operational guide is the fundamental prerequisite for the safe and effective use of industrial laminating equipment. Before initial operation, a comprehensive review of the supplied handbook is essential. This documentation provides critical model-specific procedures, vital safety protocols, and detailed explanations of all machine functions. Ensuring complete familiarity with the control interface—including all settings, indicators, and activation mechanisms—is crucial for achieving optimal results and maintaining a secure working environment.

Prepare Your Documents

To ensure a flawless finish, proper document pre-processing is imperative. All materials must be clean, completely dry, and free from dust or particulate debris. Remove any fasteners such as staples or paper clips, as these can severely damage the laminator’s rollers and compromise the seal. Correct alignment within the film or pouch is also critical; ensure the item is positioned squarely with an adequate border to allow for a complete peripheral seal. This meticulous preparation is the most effective step for preventing operational issues and guaranteeing consistently professional, bubble-free results.

Adjust Temperature and Speed Settings

Optimal lamination requires precise thermal calibration tailored to the specific substrate. Always refer to the machine’s operational manual and the laminating film manufacturer’s guidelines to establish the correct temperature and feed rate. Achieving a perfect, durable bond depends on finding the precise equilibrium between these two settings; an incorrect balance can lead to poor adhesion, bubbling, or material distortion.

Allow the Laminator to Warm Up

Professional-grade laminators require an initial heating period to reach thermal stabilisation. Consult the unit’s manual for the precise duration, which varies by model. Operating the machine before it attains the correct, consistent temperature will result in substandard adhesion and finish quality. Always allow for complete warm-up prior to commencing any lamination task.

Feed the Documents into the Laminator

Once the machine has stabilised at the correct operating temperature, you may commence the lamination process. It is critical to feed materials in a straight, steady, and even manner to prevent jams, misalignment, or wrinkles that compromise the final finish.

For pouch laminators, securely position the document within the pouch and insert it with the sealed edge leading into the machine’s feed tray. For roll laminators, carefully align the leading edge of your document with the laminating film before guiding both through the entry point simultaneously. Consistent, straight feeding is the key to achieving perfectly sealed, professional results with every item.

Monitor the Laminating Process

To ensure flawless results, continuous monitoring of the lamination process is essential. Observe the material’s passage through the machine for any indications of misalignment, wrinkling, or hesitation that could signal an impending jam. Should any irregularities appear in the finished product—such as air bubbles, poor edge adhesion, or inconsistent gloss—promptly pause and recalibrate the temperature or speed settings as necessary. Immediate intervention and adjustment are key to maintaining consistent, professional output and preventing material waste.

Allow Sufficient Cooling Time

Industrial-grade laminating systems deliver distinct operational advantages that substantiate their value in professional settings. Their primary strength lies in exceptional durability, derived from heavy-duty components engineered for sustained performance under continuous use. This robust construction enables reliable processing of diverse materials, from wide-format items to high-volume batches, ensuring long-term dependability.

Furthermore, these machines guarantee consistently professional finishes through advanced technical controls. Precision-adjustable temperature settings and variable processing speeds allow for exact calibration to specific material requirements, ensuring optimal adhesion and a flawless, bubble-free finish on every project. This technical control is often complemented by integrated safety features such as thermal auto-shutoff, which protects both the materials and the equipment.

A key productivity benefit is their efficiency. Engineered for rapid warm-up and higher operational speeds, these laminators significantly accelerate workflow, reducing turnaround times for large volumes. This enhanced throughput directly translates to lower effective labour costs and increased daily output, making them a strategic investment for enhancing departmental productivity and overall operational efficiency.

Trim and Finish

After the laminated item has fully cooled and the adhesive has completely set, a final trimming step ensures a professionally finished product. Carefully remove any excess film or overhanging pouch edges using a sharp utility knife, precision paper trimmer, or guillotine cutter, depending on the item’s size and thickness. Execute clean, straight cuts to achieve neat, flush edges. This attention to detail results in a polished, ready-to-use document, sign, or display item with a perfectly sealed and trimmed border.

Maintenance and troubleshooting tips for heavy duty laminator machines

A rigorous preventative maintenance regimen is fundamental to ensuring the long-term reliability, performance, and safety of a commercial laminating system. Consistent care and timely intervention are the most effective strategies for preventing operational downtime and preserving output quality. Below are essential protocols for the upkeep and basic troubleshooting of these machines.

Regular Cleaning

Adhering to a meticulous cleaning protocol is paramount for maintaining the performance and longevity of a heavy-duty laminating machine. Residue from adhesives, along with accumulated dust and paper fibres, can compromise roller performance and final finish quality. The cornerstone of proper care is strict adherence to the manufacturer’s specific cleaning guidelines for your model.

Generally, the process involves using a soft, lint-free cloth, slightly dampened with the manufacturer-recommended cleaning solution or isopropyl alcohol, to gently wipe down all accessible rollers and surfaces. It is critical to avoid abrasive pads, harsh chemicals, or excessive moisture, as these can permanently damage the rollers’ sensitive coatings and internal components. Implementing this routine after high-volume use or when switching film types prevents contamination and ensures consistently professional, bubble-free lamination results.

Lubrication

A professional maintenance schedule for heavy-duty laminators may include the periodic lubrication of specific moving parts to ensure optimal performance and prevent premature wear. The necessity, frequency, and type of lubricant required are exclusively determined by the manufacturer’s specifications for your particular model.

Critical Guidelines for Proper Lubrication:

- Consult the Manual: Always refer to the user manual to identify which components (if any) require lubrication, the correct lubricant type, and the recommended service interval.

- Apply Sparingly: If lubrication is required, apply the specified lubricant extremely sparingly. Excess lubricant can migrate onto rollers or the film path, contaminating materials and causing adhesive failure on future laminating jobs.

- Avoid General-Purpose Oils: Never use general-purpose household oils or sprays, as they may not be suitable for the high temperatures and plastics within the machine and could cause damage.

Adhering strictly to these guidelines protects the mechanism, maintains consistent output quality, and is an integral part of a comprehensive preventative maintenance strategy.

Inspect and Replace Worn Parts

Conducting scheduled visual inspections is a cornerstone of preventative maintenance for commercial-grade laminators. Focus particularly on the condition of the heated and pressure rollers, as any wear, cracking, glazing, or surface irregularity will directly compromise adhesion and finish quality, leading to bubbles or wrinkles. The timely replacement of worn rollers is essential.

A comprehensive check should also include an examination of the feed mechanism, guides, and electrical control panel for any signs of damage, misalignment, or fault. Identifying and addressing minor issues, such as a loose component or a flickering indicator, during these routine inspections can prevent them from escalating into major operational failures, ensuring consistent performance and prolonging the equipment’s serviceable life.

Address Jams and Misalignments

Should a jam or material misalignment occur, a prompt and methodical response is essential. Adhere strictly to the manufacturer’s specified clearance procedure, which typically involves engaging the machine’s reverse function, if available, or following a prescribed safe-access protocol. It is critical to avoid using excessive force or sharp implements to extract the material, as this can permanently damage the precision rollers and heating elements.

Persistent jams, recurring misalignment, or any issue you cannot confidently resolve using the official guide indicate a potential mechanical fault. In such instances, immediately cease operation and contact the manufacturer’s technical support or a certified service technician for diagnosis and repair. This approach safeguards both the equipment’s integrity and operator safety.

Keep the Laminator in a Suitable Environment

To maintain a heavy-duty laminator’s operational integrity and service life, providing an appropriate working environment is crucial. The equipment should be situated in a controlled setting, shielded from extreme temperatures, excessive humidity, and direct sunlight, all of which can impair mechanical and thermal performance. Position the unit on a stable, level surface to prevent disruptive vibrations or movement during operation, which is essential for achieving consistent, high-quality results. Adhering to the manufacturer’s specified environmental and installation guidelines ensures the machine functions within its designed parameters, safeguarding your investment and guaranteeing reliable, long-term performance. Proactively managing these conditions is a fundamental aspect of professional equipment care.

Conclusion and final recommendations

Investing in an industrial-grade laminating system represents a fundamental upgrade, offering superior resilience, professional-grade output, and unmatched operational capacity. Designed for sustained, high-volume use, these machines adeptly handle diverse material sizes and weights. Their advanced functionality—including precision temperature calibration, variable speed control, and intelligent features like thermal auto-shutoff—provides exceptional control, ensuring flawless finishes for any project.

When selecting a machine, prioritise specifications that align directly with your workflow: processing speed, maximum material width, adjustable thermal settings, and integrated safety mechanisms. Furthermore, a regime of committed, preventative care is essential for preserving the equipment’s performance and longevity over time.

This strategic investment transforms lamination from a manual task into a reliable, efficient cornerstone of your finishing department. By leveraging the power and precision of a heavy-duty system, you achieve consistent, durable results that protect important documents and enhance your professional output.