Benefits of using hydraulic guillotine paper cutters

Hydraulic guillotine cutters provide significant operational advantages for commercial and industrial printing environments. Their primary benefit is exceptional cutting precision. Powered by a consistent hydraulic mechanism, these machines deliver a perfectly uniform blade action, effortlessly producing clean, sharp cuts through substantial material stacks without ragged edges or dimensional variance.

A further critical advantage is their high-volume productivity. Engineered for rapid, continuous operation, hydraulic cutters drastically reduce processing time for large batches. This efficiency is essential for meeting demanding production schedules and improving overall workflow throughput.

Additionally, these systems offer remarkable material versatility. Beyond standard paper stocks, they can accurately process a diverse range of substrates, including thick cardboard, corrugated sheets, and certain polymers. This capability makes them indispensable for a wide array of finishing tasks, from precise business card trimming to the bulk production of marketing brochures and promotional materials.

Factors to consider when choosing a hydraulic guillotine paper cutter

Selecting an industrial guillotine cutter requires a methodical evaluation of key technical specifications to match your operational needs and safety standards. A structured assessment will guide you to the most suitable and productive machine.

Assess Cutting Dimensions & Material CapacityFirst, determine the maximum cutting width required for your typical materials, ensuring the machine’s bed size accommodates your largest standard substrate. Next, evaluate the sheet capacity (ream height) the cutter can process in one cycle. For high-volume environments, a model with a robust capacity is essential to maintain workflow efficiency and avoid bottlenecks.

Prioritise Advanced Safety EngineeringOperator safety is non-negotiable. Beyond basic guards, prioritise models with integrated safety features such as a two-hand activation system, safety light curtains, and automatic blade brakes. These engineered safeguards are paramount for preventing accidents and ensuring compliant operation in a busy workshop.

By systematically analysing these factors—cutting width, sheet capacity, and safety systems—you can invest with confidence in a machine that delivers precise performance, enhances productivity, and provides a secure working environment.

Understanding the different types of hydraulic guillotine paper cutters

Industrial hydraulic guillotine cutters are categorised into distinct operational types to suit varying production demands and investment levels: manual, semi-automatic, and fully automatic systems.

Manual hydraulic cutters require complete operator control, including guided paper alignment and physical initiation of the cutting cycle. These models represent a cost-effective entry point, best suited to workshops with lower-volume requirements or less frequent use.

Semi-automatic models enhance efficiency by automating the cutting action itself. Operators manually position the material stack, after which the machine automatically executes the precise hydraulic cut. This type is ideal for businesses with moderate, regular throughput seeking to improve speed and consistency without a fully automated investment.

Fully automatic hydraulic cutters offer the highest level of productivity. They integrate automated paper feeding, alignment, and cutting into a seamless cycle, minimising manual intervention. These systems are designed for high-volume industrial environments where maximising throughput and operational efficiency is paramount.

Key features to look for in a hydraulic guillotine paper cutter

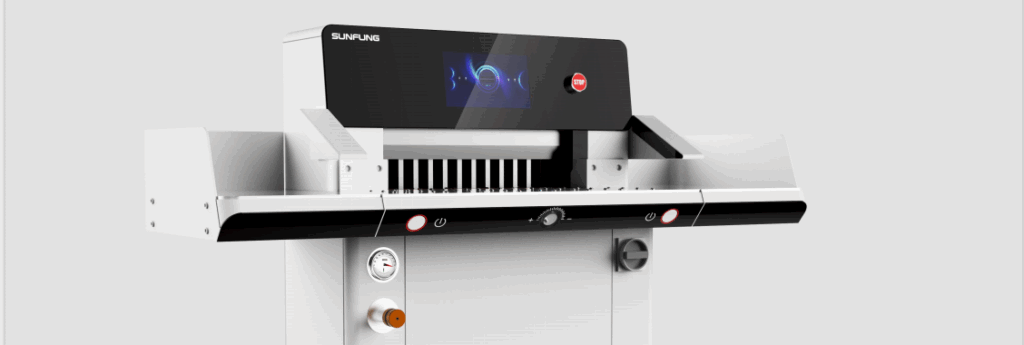

Selecting an industrial hydraulic guillotine cutter necessitates a detailed evaluation of its core mechanical and control systems. Three pivotal features critically influence performance, precision, and long-term operational value.

Cutting Blade Composition & QualityThe blade is the fundamental component for performance. Prioritise cutters equipped with blades forged from high-carbon steel or tungsten carbide. A premium, durably sharp blade is essential for maintaining clean, precise incisions over thousands of cycles, directly reducing long-term maintenance costs and ensuring consistent output quality.

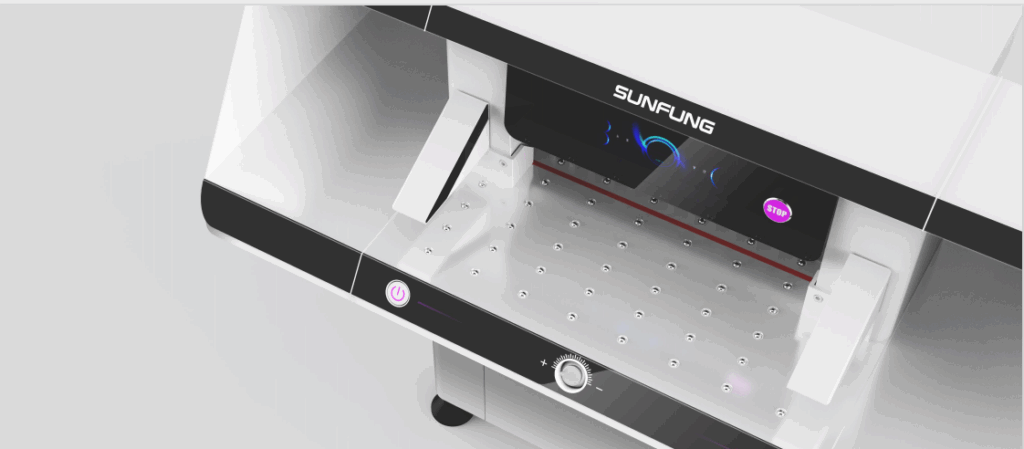

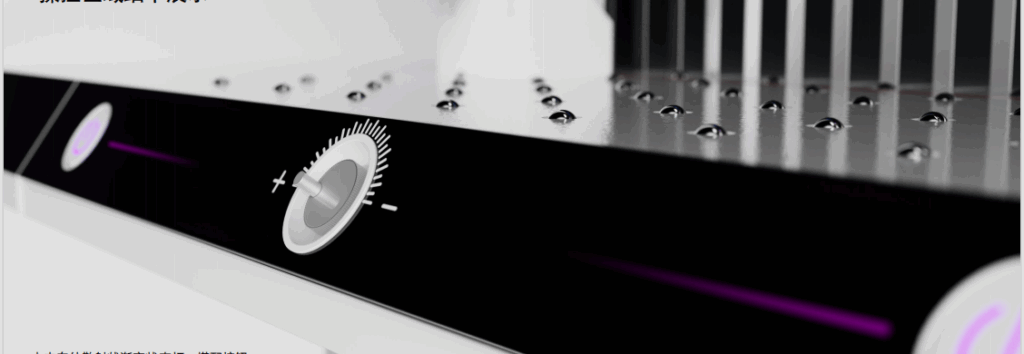

Robust Hydraulic Clamping SystemAn effective, high-pressure clamping mechanism is crucial for accuracy. It must securely immobilise the entire material stack before and during the cut to prevent slippage. Opt for a system with adjustable pressure settings to accommodate varying material densities—from fine paper to rigid board—ensuring perfect registration and flawless results across all jobs.

Advanced Programmability & AutomationFor high-throughput environments, automation features are transformative. Modern systems offer programmable memory functions to store and recall complex cutting sequences, guaranteeing repeatability. Integrated automation, such as computer-controlled backgauges and air flotation tables, significantly accelerates material handling, minimises operator intervention, and maximises overall cutting efficiency and safety.

Safety considerations for using hydraulic guillotine paper cutters

Operating a hydraulic guillotine cutter demands strict adherence to established safety protocols, with engineering controls and disciplined procedures forming the essential foundation for accident prevention.

Primary Safety EngineeringThe machine must be equipped with fixed and interlocked safety guards that completely prevent access to the cutting zone during operation. Furthermore, a mandatory two-hand control system is non-negotiable, requiring the simultaneous activation of two separate buttons to initiate a cut, thereby ensuring the operator’s hands are at a safe distance.

Proactive Maintenance RegimeSafe operation is intrinsically linked to machine condition. A strict schedule for professional blade maintenance and lubrication of all moving parts must be followed as per the manufacturer’s specifications. Coupled with routine visual inspections for wear or hydraulic leaks, this proactive upkeep is critical to preventing mechanical failures that could lead to hazardous situations.

Comprehensive Operator TrainingBeyond physical safeguards, ensuring that all personnel are thoroughly trained in the correct operating procedures, understanding of safety features, and basic emergency response is paramount for sustaining a safe working environment.

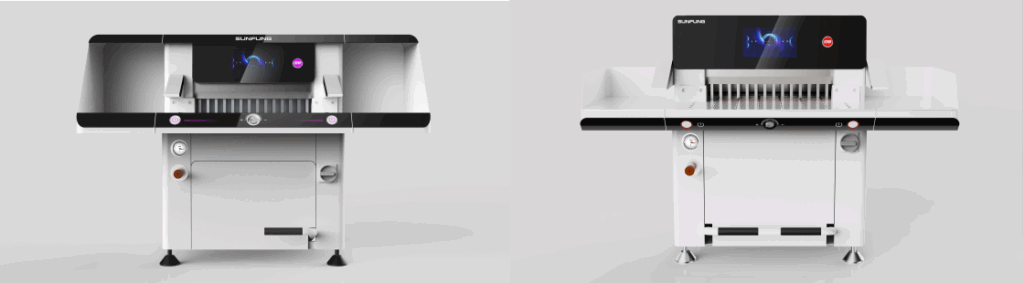

How to choose the right size of hydraulic guillotine paper cutter for your business

Selecting the correctly sized hydraulic guillotine cutter is a strategic decision impacting long-term workflow efficiency. A precise assessment should focus on two core metrics: physical dimensions and processing volume.

1. Analyse Maximum Cutting Width and Bed SizeIdentify the largest sheet dimension your projects require. The cutter’s bed must accommodate this width and length comfortably, with additional space for safe and unobstructed material handling. A common best practice is to select a machine with a cutting width at least 10-15% greater than your current maximum size to ensure versatility for future, slightly larger formats.

2. Evaluate Cutting Capacity (Stack Height)Calculate the maximum thickness (ream height) of material you need to process in a single cut. For environments handling dense, high-volume stacks, a machine with a robust capacity is non-negotiable to maintain productivity and avoid the inefficiency and potential inaccuracy of multiple partial cuts.

3. Incorporate Future Growth ProjectionsAdopt a forward-looking investment strategy. If business expansion is anticipated, choosing a model with superior capacity and a wider bed from the outset protects against premature obsolescence. This foresight mitigates the need for a costly secondary investment and operational disruption as your production demands increase.

By methodically evaluating these parameters—current maximum size, daily volume, and projected growth—you can invest in a machine that delivers optimal performance today while providing the scalability to support your business’s future development.

Conclusion: Finding the perfect hydraulic guillotine paper cutter for your business needs

Selecting an optimal hydraulic guillotine cutter is a strategic decision that hinges on a precise evaluation of several interdependent factors. A methodical analysis of your specific cutting requirements—encompassing maximum material dimensions, operational volume, necessary safety certifications, and the appropriate level of automation—is fundamental to identifying a machine that will enhance productivity, operational safety, and long-term workflow efficiency.

Acquiring a robust, precision-engineered cutter constitutes a direct investment in your operational capability. These systems deliver transformative benefits, including exacting cut quality, the ability to process diverse substrates, and significant workflow acceleration, making them indispensable for any business reliant on high-volume, professional document finishing.

Throughout the selection process, advanced safety engineering must be the foremost priority. Essential features include integrated safety guards, mandatory two-hand control systems, and optical protection devices. Furthermore, committing to the manufacturer’s prescribed preventative maintenance schedule and conducting regular inspections are non-negotiable practices for ensuring sustained safe performance and protecting your personnel.

By rigorously applying this structured approach to your procurement process, you can confidently secure a guillotine cutter that not only meets your immediate technical specifications but also delivers enduring value, driving productivity and reinforcing the professional standard of your output.