In the modern commercial sector, optimising operational workflows is essential. Managing high volumes of paperwork presents a common efficiency challenge. Automated paper folding machines provide a decisive solution to this bottleneck. Fundamentally, this equipment automates the process of creating precise, consistent folds in documents.By eliminating manual folding, these systems save considerable time and reduce labour costs. They are indispensable in environments with substantial document throughput, including commercial printing houses, mailing distribution centres, and corporate offices, where speed, accuracy, and reliability in document finishing are paramount.

How do Paper Folder Machines Work?

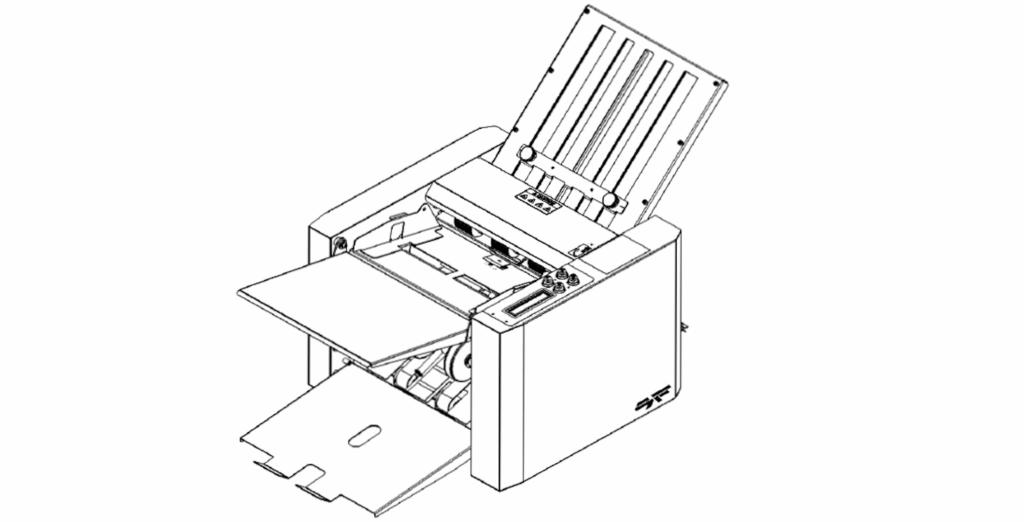

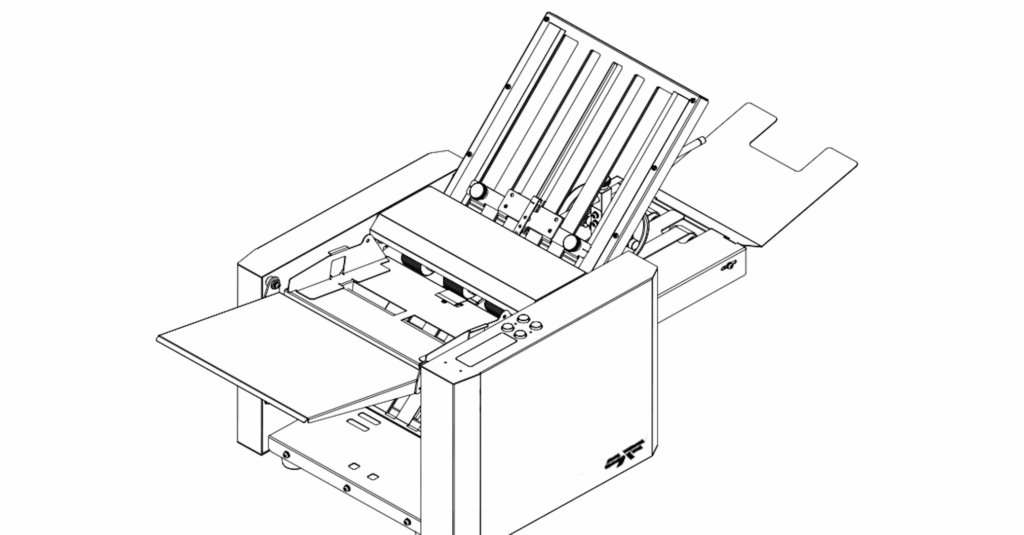

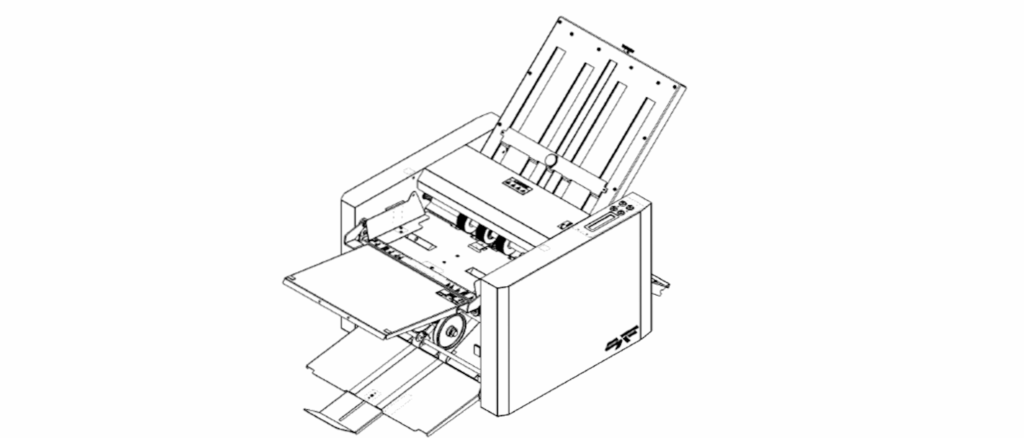

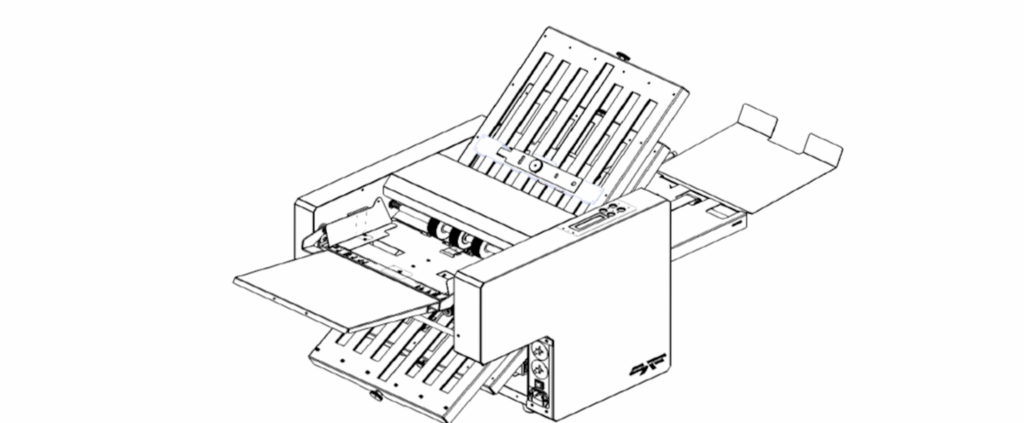

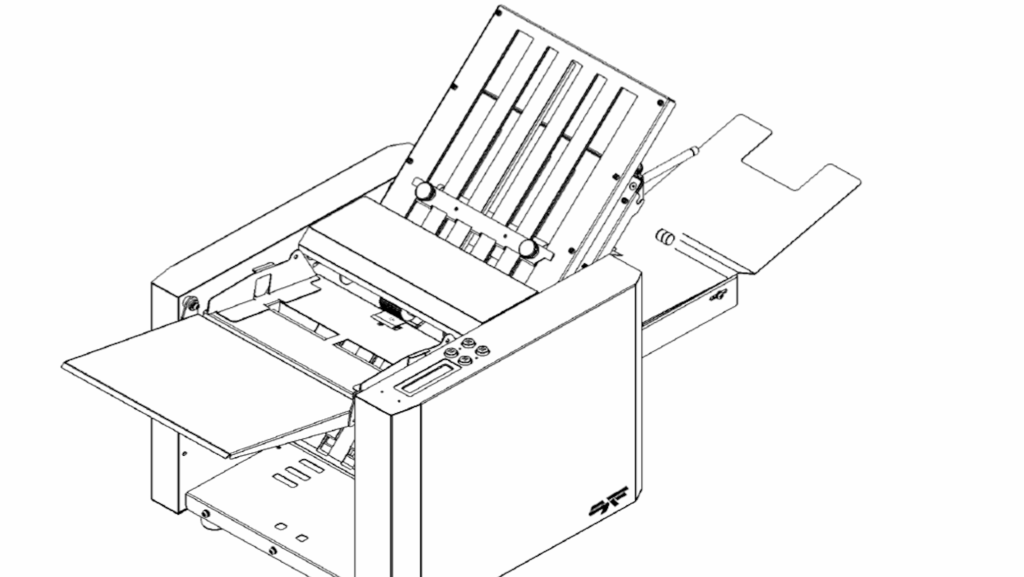

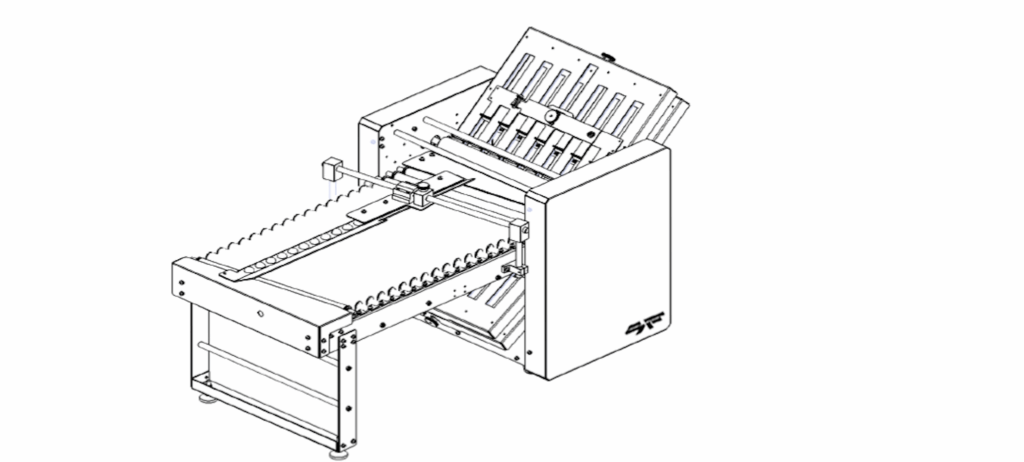

An automated paper folder executes its function through a coordinated mechanical process. The core mechanism employs precisely calibrated rollers and adjustable folding plates to guide each sheet into the desired configuration.

Operation commences with loading a stack of paper into the feed tray. Driven rollers then smoothly draw each sheet into the machine, ensuring correct alignment. The paper is transported through the system, where it encounters the set folding plates. These plates, which can be configured for specific patterns such as a letter fold, accordion fold, or double parallel fold, direct the paper’s path. Subsequent roller pairs create sharp, precise creases at the designated points. Finally, the accurately folded document is delivered to the output tray, completed and ready for the next stage of processing or dispatch.

Benefits of Using Paper Folder Machines

Acquiring an automated paper folding system delivers tangible operational advantages. Primarily, it eliminates the substantial time dedicated to manual folding, processing hundreds of sheets per minute. This automation reallocates human resources to higher-value tasks, driving overall productivity gains.

A key benefit is the assurance of flawless, uniform results. The machine’s precision engineering eradicates the inconsistencies of hand-folding, which is critical for maintaining the professional standard of client-facing materials like invoices, brochures, or legal documents. This accuracy streamlines subsequent handling and mailing processes.

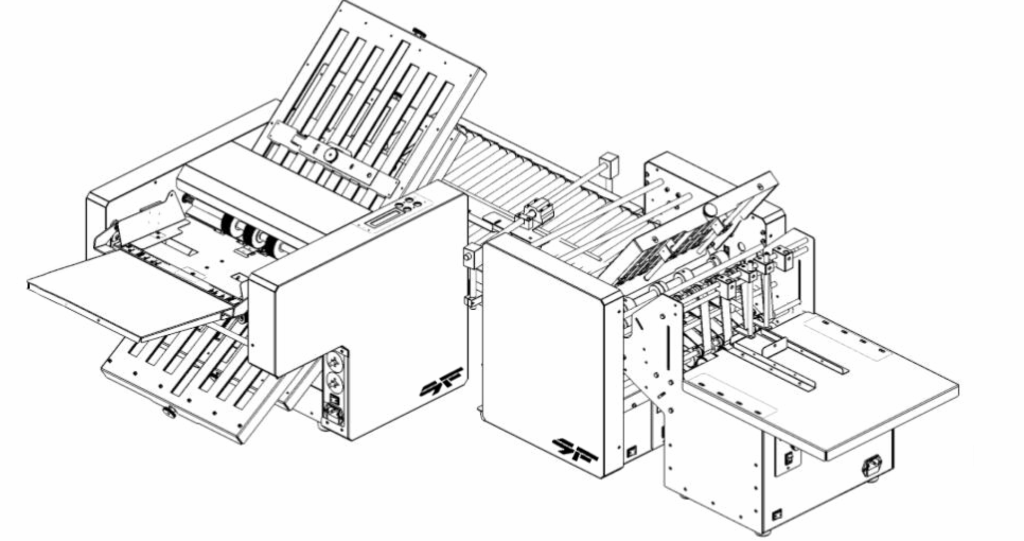

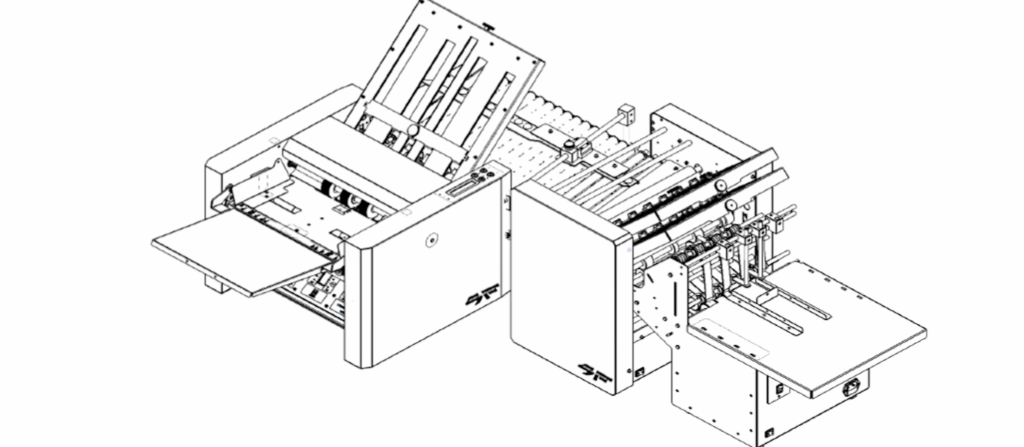

Furthermore, modern folders offer significant versatility, adeptly processing various paper sizes, weights, and finishes. Advanced models expand functionality further with integrated capabilities for tasks like creasing, perforating, or even inline stapling, consolidating multiple finishing steps into one efficient operation and enhancing overall workflow flexibility.

Types of Paper Folder Machines

There are several types of paper folder machines available on the market, each designed to meet different folding needs. The most common types include:

Friction Feed Paper Folder Machines: These machines use friction rollers to pull the paper in and fold it. They are suitable for folding standard-sized paper and are ideal for small to medium-sized businesses.

Air Feed Paper Folder Machines: These machines use air suction to feed the paper and create folds. They are capable of handling a wide range of paper sizes and thicknesses, making them suitable for high-volume printing and mailing operations.

Automatic Paper Folder Machines: These machines offer fully automated operation, from feeding the paper to creating precise folds. They are equipped with advanced features such as programmable settings and batch processing, making them ideal for large-scale production environments.

Factors to Consider When Choosing a Paper Folder Machine

Selecting the optimal paper folding system requires a methodical evaluation of core technical and operational specifications. Focusing on the following criteria will ensure your investment aligns with your workflow demands and delivers maximum return.

Key Assessment Criteria

- Material Specifications: Precisely assess the standard sizes, weights (gsm), and finish of the paper stocks you routinely process. The chosen machine must reliably accommodate this range without compromise to feed stability or fold quality.

- Throughput Capacity: Quantify your average and peak daily folding volume. Selecting a model with a duty cycle and input tray capacity that meets or exceeds this demand is crucial to prevent operational bottlenecks and maintain smooth workflow continuity.

- Operational Efficiency: Evaluate the machine’s rated speed (sheets per hour) alongside its first-sheet-out time. A balance of high sustained throughput and quick job setup is essential for overall efficiency, particularly when handling multiple, smaller batches.

- User Interface & Ergonomics: Prioritise systems with an intuitive control interface, often featuring programmable memory for frequent jobs. Additionally, consider ease of loading and simple, tool-free adjustments for fold plates, which significantly reduce setup time and operator training requirements.

A focused analysis based on these parameters will guide you to a machine that provides robust performance, seamless integration into your processes, and sustained long-term value.

When evaluating a paper folding system, the long-term cost of ownership and operational reliability are significantly influenced by its maintenance profile and the manufacturer’s support framework.

A structured, preventative maintenance schedule is critical to sustaining optimal performance and extending the machine’s service life. Prioritise models designed for ease of upkeep, with accessible components for routine cleaning and adjustment.

Equally vital is securing access to responsive, professional technical support. Verify the manufacturer or distributor offers clear channels for troubleshooting, readily available genuine spare parts, and qualified service technicians. This support infrastructure is essential for minimise costly operational downtime and protecting your productivity.

Common Features and Functionalities of Paper Folder Machines

Modern paper folding systems incorporate advanced technical features designed to enhance versatility, efficiency, and operational reliability. Key functionalities to prioritise include:

Precision-Adjustable Mechanisms: Systems feature precision-adjustable folding plates or rollers, enabling quick configuration for a wide range of fold patterns—from standard letter folds to complex accordion or gatefold styles—to meet diverse project requirements.

Automated Batch & Memory Functions: For high-volume efficiency, programmable batch counters automate the processing of set quantities. Furthermore, digital memory settings allow users to store and instantly recall precise configurations for different paper types and fold styles, ensuring consistency and eliminating setup time for repeat jobs.

Intelligent Feed & Error Management: Sophisticated ultrasonic or mechanical double-feed detectors prevent multiple sheets from entering the fold path simultaneously, safeguarding against jams and inaccuracies. Integrated diagnostic systems provide real-time error alerts and guided clearance procedures, significantly reducing downtime and simplifying troubleshooting.

These integrated features transform a basic folding unit into a robust, intelligent component of a streamlined document finishing line, directly contributing to higher throughput, reduced waste, and consistent output quality.

Tips for Using a Paper Folder Machine Effectively

To ensure your paper folding system operates at peak performance and delivers consistent, professional results, adhering to these operational best practices is essential.

1. Prepare Stock CorrectlyAlways use paper that is clean, dry, and completely flat when loading it into the feed tray. Pre-fan the stack to separate sheets and check for any curled edges or adhered sheets, as these are primary causes of misfeeds and jams.

2. Calibrate Folding Mechanisms PreciselyAccurately align and calibrate the folding plates or rollers for the specific fold pattern required. Ensure all locking mechanisms are securely fastened after adjustment to prevent any drift during operation, which would compromise fold accuracy.

3. Adhere to a Proactive Maintenance ScheduleStrictly follow the manufacturer’s maintenance protocol. This includes regular cleaning of feed rollers and paper paths, applying specified lubricants to moving parts at recommended intervals, and promptly replacing any worn components to maintain optimal mechanical function.

4. Conduct Preliminary TestingBefore commencing a full production run, always execute a test fold using a sample of the actual stock. This verifies the machine’s calibration, ensures fold placement is correct, and allows for any necessary fine-tuning, thereby preventing material waste on a large scale.

5. Implement Comprehensive Operator TrainingEnsure all personnel are thoroughly trained not only in basic operation but also in proper setup, routine maintenance procedures, and basic troubleshooting. Standardised, competent operation minimises errors, reduces wear, and protects your investment.

By systematically integrating these practices—preparation, precise calibration, scheduled upkeep, pre-job verification, and skilled operation—you will maximise throughput, ensure unwavering quality, and extend the service life of your equipment.

Maintenance and Troubleshooting of Paper Folder Machines

To ensure sustained reliability and peak performance, implementing a structured maintenance regimen for your paper folding system is essential. A proactive approach to upkeep safeguards your investment and prevents operational downtime.

Core Maintenance Protocol

1. Adhere to a Preventative ScheduleEstablish and strictly follow a periodic maintenance schedule based on the manufacturer’s specifications and your usage intensity. Consistency is key to preventing minor issues from escalating.

2. Execute Systematic CleaningRegularly clean all critical components, including feed rollers, paper pathways, and folding plates, using a soft, lint-free cloth to remove dust, paper fibres, and debris. This prevents the most common causes of jams and feeding inaccuracies.

3. Apply Precision LubricationLubricate moving parts only with the manufacturer-recommended lubricant and at the intervals specified in the manual. Proper lubrication minimises wear on bearings, gears, and slides, ensuring quiet and smooth operation.

4. Monitor and Proactively Replace Worn PartsRoutinely inspect high-wear components such as pickup rollers, drive belts, and fold plates for signs of wear, cracking, or glazing. Proactively replacing these consumable parts before failure is more cost-effective than dealing with a breakdown during production.

5. Seek Authorised Technical SupportFor complex faults, performance issues, or annual servicing, engage a qualified technician from the manufacturer or an authorised service partner. Their expertise ensures accurate diagnostics, genuine parts, and calibrations that preserve the machine’s precision and warranty coverage.A disciplined commitment to these practices—scheduled cleaning, correct lubrication, proactive part replacement, and expert servicing—directly translates to extended machine lifespan, consistent output quality, and maximised productivity.

Conclusion – Is a Paper Folder Machine Right for Your Business?

In summary, automated paper folding systems deliver substantial operational benefits for businesses managing high-volume document workflows. They enhance operational throughput, ensure precision finishing, and achieve consistent output. Prior to investment, a methodical evaluation of your specific requirements—including paper specifications, volume capacity, and essential functionalities—is crucial. Selecting an appropriate system and adhering to a rigorous maintenance protocol will streamline your document processing, significantly boosting overall productivity.

Ultimately, a professional-grade folder represents a strategic capital investment in your business’s operational efficiency. For any organisation allocating excessive labour hours to manual folding, adopting this technology is a definitive step towards optimised, professional document handling.